Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

Water Connections

Liebert

®

CRV

™

30

7.2 Glycol Mixture

Add ethylene glycol or propylene glycol to the circuit in the percentages shown in Table 18.

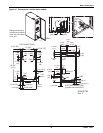

7.3 Water Connections: Water/Glycol-Cooled Models

The unit must receive cooling water as follows:

• From an external cooling water source, in open circuit.

• Using a drycooler, in closed circuit.

1. Connect the piping as shown in Appendix D - Refrigeration and Hydraulic Circuits.

2. Use hoses connected with three-piece joints to the condenser water inlet and outlet couplings.

3. Install a 16-20 mesh strainer on the water/glycol supply to the Liebert CRV. The strainer is

needed to prevent particles in the water from entering the unit’s heat exchanger.

4. Place shutoff ball valves at the conditioner inlet and outlet to allow easy maintenance.

5. Install a water drain system at the lowest point in the circuit.

6. Fully drain the piping before connecting it to the air conditioner.

7.3.1 Notes for Open-Circuit Applications

• Use the unit with mains or well water. Do not use water from an evaporative cooling tower unless

the water hardness is controlled.

• The water pressure must be 29-145psi (2-10 bar). If water pressure is outside this range, contact

Emerson for technical support.

• The required water flow at different temperatures is available from Emerson.

• If water temperature is very low, insulate both pipes.

7.3.2 Notes for Closed-Circuit Applications

The installation in Figure 3 is illustrative only; for individual installations follow the project diagram.

• Install a pump system calculated on the basis of the flow and total head of the system (see site

plan data) and controlled by the compressor running (see label on the Liebert CRV).

• Insulate both pipes.

• Very important: Add water and ethylene glycol to the circuit when the ambient temperature is

below 32°F (0°C); refer to the Liebert CRV technical data manual, SL-11978). Do not exceed the

nominal operating pressure of the circuit components.

• Bleed air out of the circuit.

Table 18 Glycol mixtures

Glycol Percentage *

by Volume

Ethylene Glycol -

Freezing Temperature, °F (°C)

Propylene Glycol -

Freezing Temperature, °F (°C)

0% 32 (0) 32 (0)

10% 25.3 (-3.7) 28.9 (-1.7)

20% 16 (-8.9) 18.7 (-7.4)

30% 3.7 (-15.7) 8.4 (-13.1)

40% -12.6 (-24.8) -6.7 (-21.5)

* Freezing temperatures may vary slightly among commercially available glycol products; refer to manufacturer’s specifications.