Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

4-03 19 480-1081

North Star

EPA Certied Fireplace

19. Finishing Material

Do not install combustible materials over the front

of the replace! This poses a safety hazard and may

start a re. You may only use noncombustible material

over the front of the replace.

a. Combustible Material

Material which is made of or surfaced with wood,

compressed paper, plant bers, plastics, or any

material capable of igniting and burning, whether

ame proofed or not, plastered or unplastered.

b. Noncombustible Material

Material which will not ignite and burn. Such

materials are those consisting entirely of steel, iron,

brick, tile, concrete, slate, glass or plasters, or any

combination thereof.

c. Noncombustible Sealant Material

Sealants which will not ignite and burn; General

Electric RTV103 Black (or equivalent), Rutland, Inc.

Fireplace Mortar #63 (or equivalent).

After completing the framing and applying the facing

material (dry wall) over the framing, a 1/2” wide

(maximum) bead of noncombustible sealant must

be used to close off any gaps at the top and sides

between the replace and facing to prevent cold

air leaks.

Only noncombustible materials may be used to

cover the metal replace front.

d. Cardboard OR Metal Template

A cardboard template of the front is printed on the

outside of the shipping box. It measures 1/8” bigger

all the way around than the actual front. Cut out the

template for use in your installation.

A metal template is also available for more durable

continued use remaining accurate over time.

The part number for this metal template is HHT-

Template.

21. Mantel

A combustible mantel may be positioned no lower than

60” from base of the replace. The combustible mantel

may have a maximum depth of 12”. Combustible trim

pieces that project no more than 1-1/2” from the face of

the replace can be placed no closer than 6” from the

side of the replace decorative front. Combustible trim

must not cover the metal surfaces of the replace. This

mantel clearance is in accordance with Section 7-3.3.3

of ANSI/NFPA211.

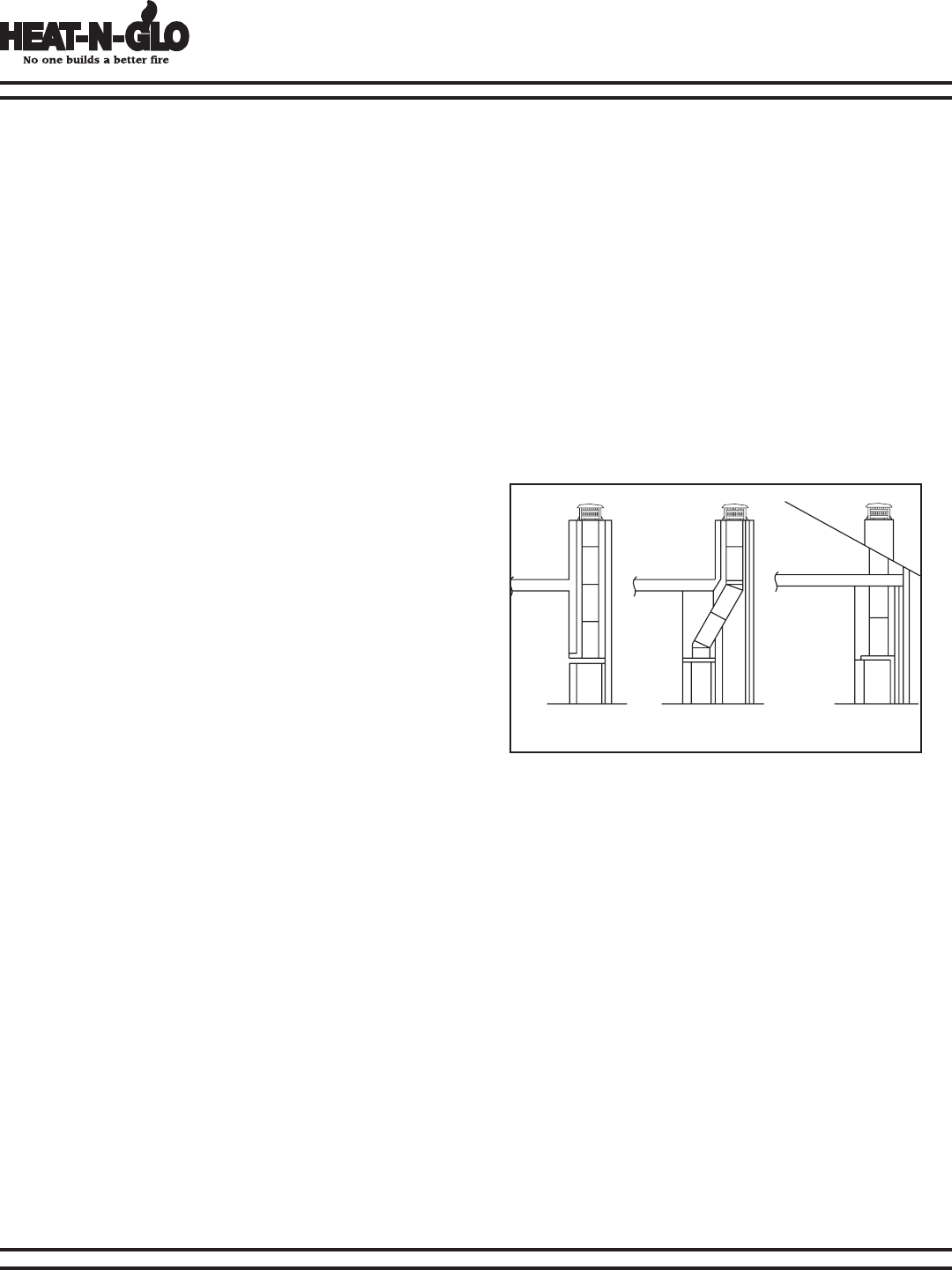

H. CONSTRUCTING A CHASE

1 2 3

Figure 19A - Chase Constructions

1. Materials

a. The chase is constructed using framing materials

much the same as the walls in your home. A variety

of siding materials may be used including brick,

stone, veneer brick, or standard siding materials.

b. In constructing the chase, several factors must

be considered:

1) Maintain a 2” air space around the chimney.

2) The chase top must be constructed of noncom-

bustible material.

3) In cold climates, a restop spacer should be

installed in an insulated false ceiling at the 8’

level above the replace assembly. This reduces

heat loss through the chase.

4) In cold climates, the walls of the chase should

be insulated to the level of the false ceiling

as shown in Figure 20A on page 20. This will

help reduce heat loss from the home around

the replace.

A chase is a vertical boxlike enclosure built around the

chimney and replace. A chase may be constructed for the

replace and chimney or for the chimney only. It is most

commonly constructed on an outside wall.

In cold climates, it is recommended that the chase oor

be insulated using batt type insulation between the oor

joists.

Three examples of chase applications are shown in Figure

19A.

1. Fireplace and chimney enclosed in an exterior

chase.

2. Chimney offset through exterior wall and enclosed

in chase.

3. Chase constructed on roof.