Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

8

106497

DIRECT-VENT FIREPLACE

®

INSTALLATION FOR

HORIZONTAL TERMINATION

1. Determine the route your horizontal

venting will take.

Note:

The location

of the horizontal vent termination on the

exterior wall must meet all local and

national building codes and must not be

easily blocked or obstructed.

Snorkel terminations are available for

terminations requiring a vertical rise on

the exterior of the building (see Figures

9 and 10). Snorkel kit SVK is also avail-

able (see page 15). Follow the same in-

stallation procedures as used for stan-

dard horizontal terminations. If install-

ing the snorkel termination below grade

(basement applications), you must pro-

vide proper drainage to prevent water

from entering the snorkel termination

(see Figure 10). Do not back fill around

the snorkel termination.

VENTING

INSTALLATION

Continued

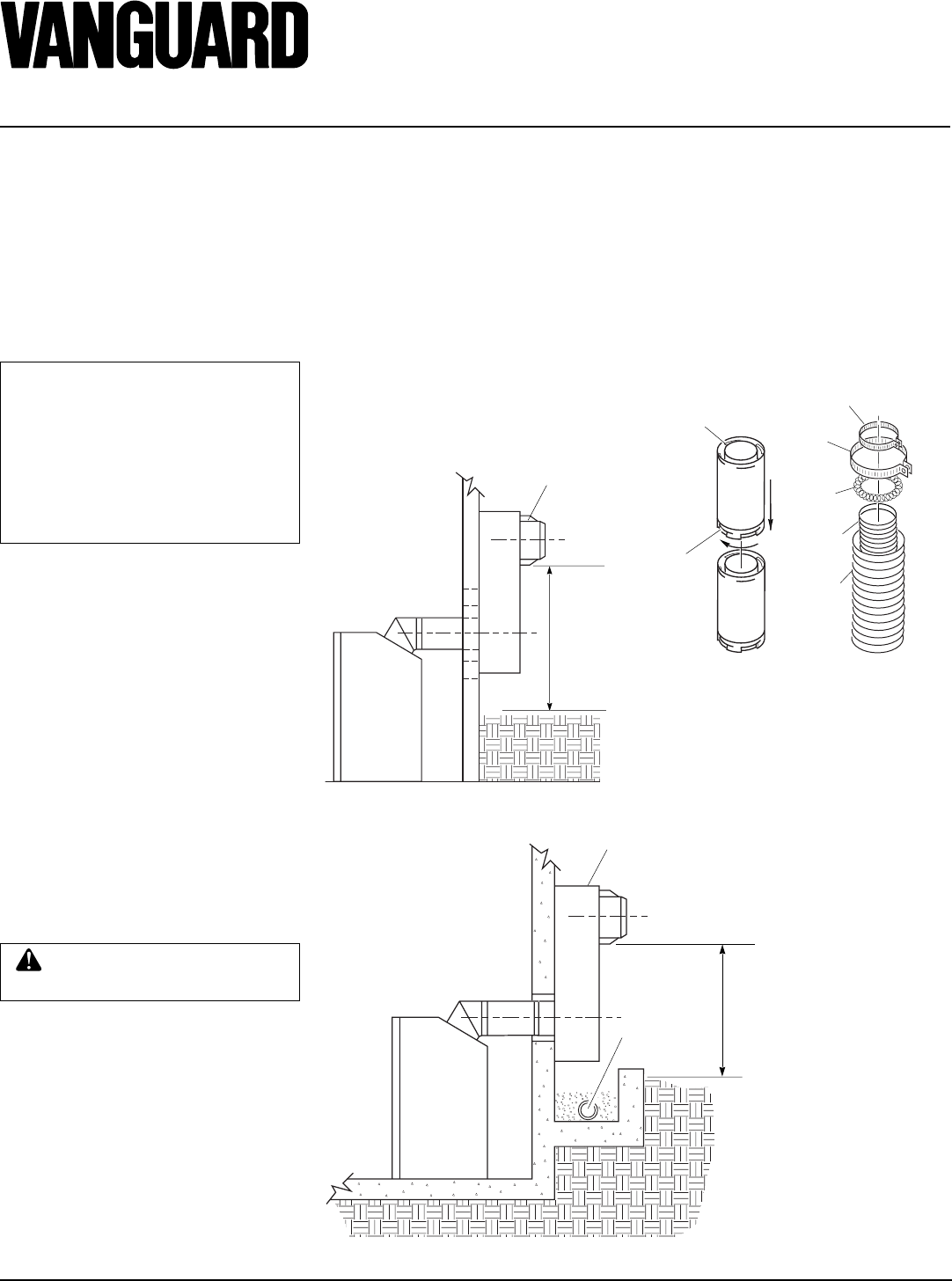

Figure 10 - Snorkel Termination with Drainage Pipe

Figure 9 - Snorkel Termination

WARNING: Do not recess vent

terminal into a wall or siding.

Figure 11 - Vent Pipe Connections

Female

Locking

Lugs

Male

Slots

Rigid Vent Pipe Flexible Vent Pipe

Spacer

Spring

4" Clamp

7" Clamp

4" Flex

Pipe

7" Flex

Pipe

Adequate

Drainage

12" Minimum

Snorkel

Snorkel

NOTICE: Treatment of firestops

and construction of the chase may

vary from building type to build-

ing type. These instructions are

not substitutes for the require-

ments of local building codes. You

must follow all local building

codes .

Note:

When installing in a chase, you should

insulate the chase as you would the outside

walls of your home. This is especially im-

portant in cold climates. Minimum clear-

ance between vent pipes and combustible

materials such as insulation is 1".

After framing the chase (see Framing and

Finishing on pages 4 and 5) install the

vent system by following the installation

instructions.

Installing Vent System in a Chase

A chase is a vertical boxlike structure built

to enclose venting that runs along the out-

side of a building. A chase is not required for

such venting.

2. Rigid vent pipes and fittings have spe-

cial twist-lock connections. Assemble

the desired combination of pipe and el-

bows to the appliance adaptor with pipe

seams oriented towards the wall or floor.

Twist-lock Procedure: The female

ends of the pipes and fittings have four

locking lugs (indentations). These lugs

will slide straight into matching slots on

the male ends of adjacent pipes and fit-

tings. (All connections must be sealed

with high temperature silicone sealant

as specified in the second warning on

page 7.) Push the pipe sections together

and twist one section clockwise approxi-

mately one-quarter turn until the sections

are fully locked. See Figure 11.

Note:

Horizontal runs of vent must be sup-

ported every three feet. Use wall straps

for this purpose.

Flexible vent pipe must be installed with

spacer springs every 12". See Figure 11.

All connections must be clamped tightly

and sealed with high temperature sili-

cone sealant as specified in the second

warning on page 7.

12"

Minimum