Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

Vent Considerations

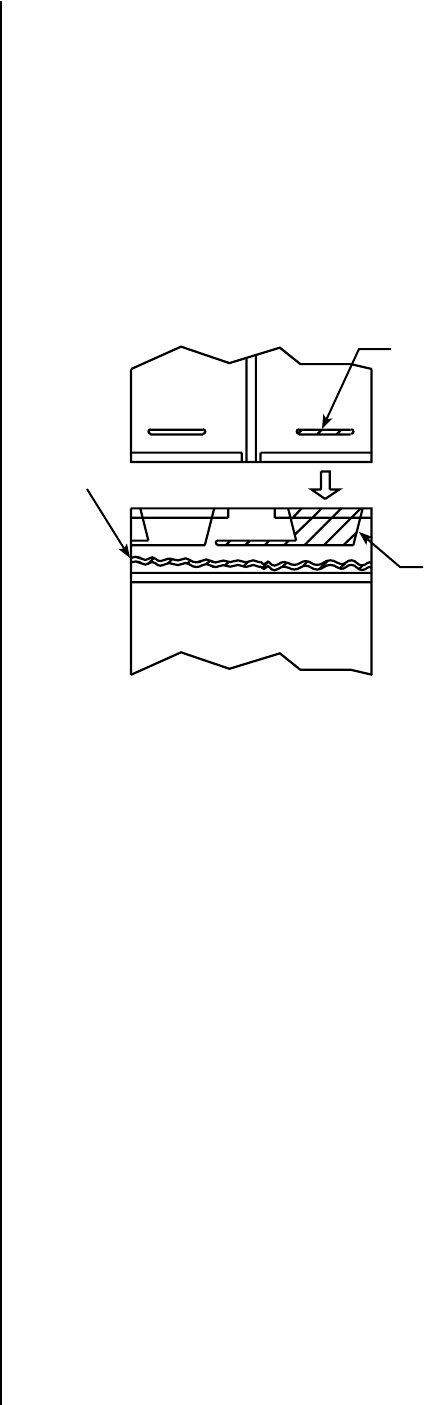

Twist-lock procedure: Four indentations, located on the female ends

of pipes and fittings, are designed to slide straight onto the male ends of

adjacent pipes and fittings by orienting the four pipe indentations so they

match and slide into the four entry slots on the male ends (see Figure

17). Push the pipe sections completely together, then twist-lock one sec-

tion clockwise approximately one-quarter turn until the two sections are

fully locked. The female locking lugs will not be visible from the outside

on the pipe or fittings. They may be located by examining the inside of

the female ends.

Supports: Horizontal runs of vent must be supported every three feet.

Wall straps are available for this purpose.

Pipe Sealing: If Security™ Secure Vent™ pipe is used, then sealant is

required at only the first pipe joint attaching the pipe to the flue collar on

the fireplace. If Simpson Dura-Vent GS pipe is used, then the pipe must

be sealed as follows: seal both the inner and outer pipes with a high

temperature silicone sealant rated for at least 600º F (commonly known

as “RTV”). Run a 1/8” (3mm) bead of silicone around the outside of the

male end of the outer sleeve. Run a 1/8” (3mm) bead of silicone about

1/4” (6mm) from the end of the male inner pipe, which is found in the

pipe to be attached above. Twist-lock the pipes or fittings together.

Figure 17

Sealant

Female

Locking

Lugs

Male

Locking

Lugs

16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.