Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

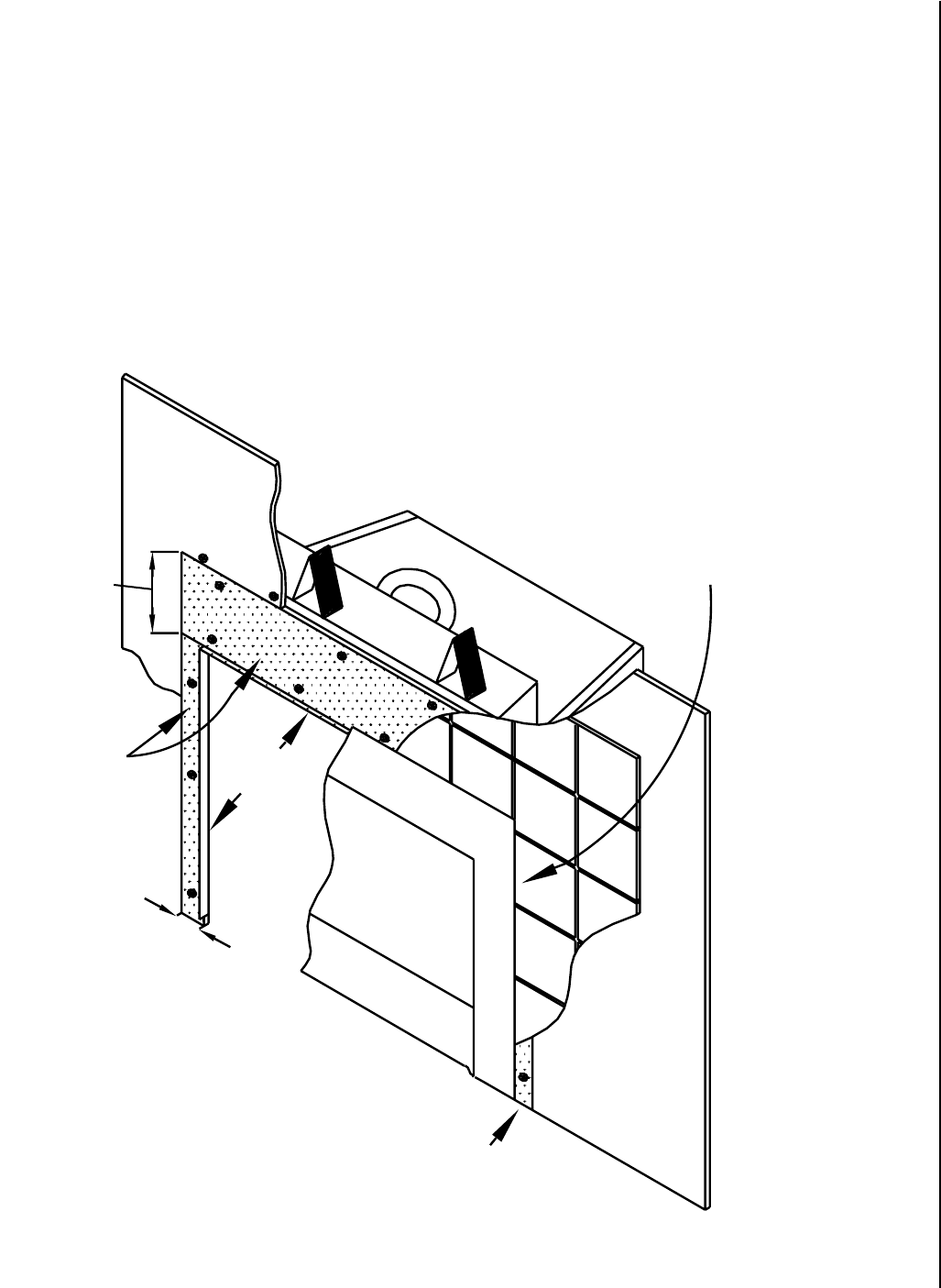

Figure 8

11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

The screws should be driven through the cement board into the outer

metal skin of the fireplace. The sheetrock (drywall) is then butted up

to the cement board. The sheetrock above the fireplace should also be

fastened to the fireplace by driving screws into the outer metal skin of

the fireplace.

Facing Less Than 1” Thick: If the combined thickness of the facing

material (eg. 3/8” [9.5 mm] thick ceramic tile and 1/2” [13 mm] thick

cement board) is less than 1” (25mm), then the tile can be placed behind

the fireplace face (see below).

Facing Installation Considerations

Non-combustible cement board (such as Wonderboard, Durock, or Har-

dybacker) must extend 10” (254 mm) above the 1” (25 mm) top reveal

and a minimum of 3” (76 mm) from each side reveal (see Figure 8

). This

cement board may be 1/4” (6.3 mm) thick or greater, but would normally

be the thickness of the drywall - for example 1/2” (13 mm). The cement

board may be fastened by drywall screws.

Cement Board

3/8” Tile and 1/2” Cement

Board Behind Fireplace Face

Cement Board - a minimum

of five inches wide.

Sheetrock

1” Reveal

5” (127mm)

Minimum

Sheetrock

3” (76mm)

Minimum

Cement Board - Minimum

of 3” (76mm) Wide

10” (254mm)

Minimum

3/8” (9.5mm) Tile and 1/2” (12.7mm) Cement Board

Behind Fireplace Face

Sheetrock

Cement Board

1” Reveal

(25mm)

Sheetrock