Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

18

106573

DIRECT-VENT GAS FIREPLACE

EVDDVF36PN and EVDDVF36STN

®

INSTALLATION

Continued

WARNING: All gas piping

and connections must be tested

for leaks after the installation is

completed.

After ensuring that the gas valve

is open, apply a soap and water

solution to all connections and

joints. If bubbles appear, leaks

can be detected and corrected.

Do not use an open flame for leak

testing and do not operate any

appliance if a leak is detected.

WARNING: Improper installa-

tion, adjustment, alteration, ser-

vice, or maintenance can cause

injury or property damage. Refer

to this manual. For assistance or

additional information, consult a

qualified installer, service

agency, or gas supplier.

GAS RATING

TYPE OF GAS NATURAL

Max. Input Rating: 30,000 Btu/hr

Orifice Size

(0-4,500 Ft.): 7/64"

Manifold Pressure: 3.5 in. WC

**Minimum Supply

Pressure: 4.5 in. WC

**Maximum Supply

Pressure: 10.5 in. WC

** For the purpose of input adjustment.

GAS SUPPLY TESTING

Note:

This section is intended as a guide for

qualified service technicians installing gas

to the appliance.

CAUTION: Do not connect

appliance before pressure test-

ing gas piping. Damage to the

gas valve may result and an un-

safe condition may be caused.

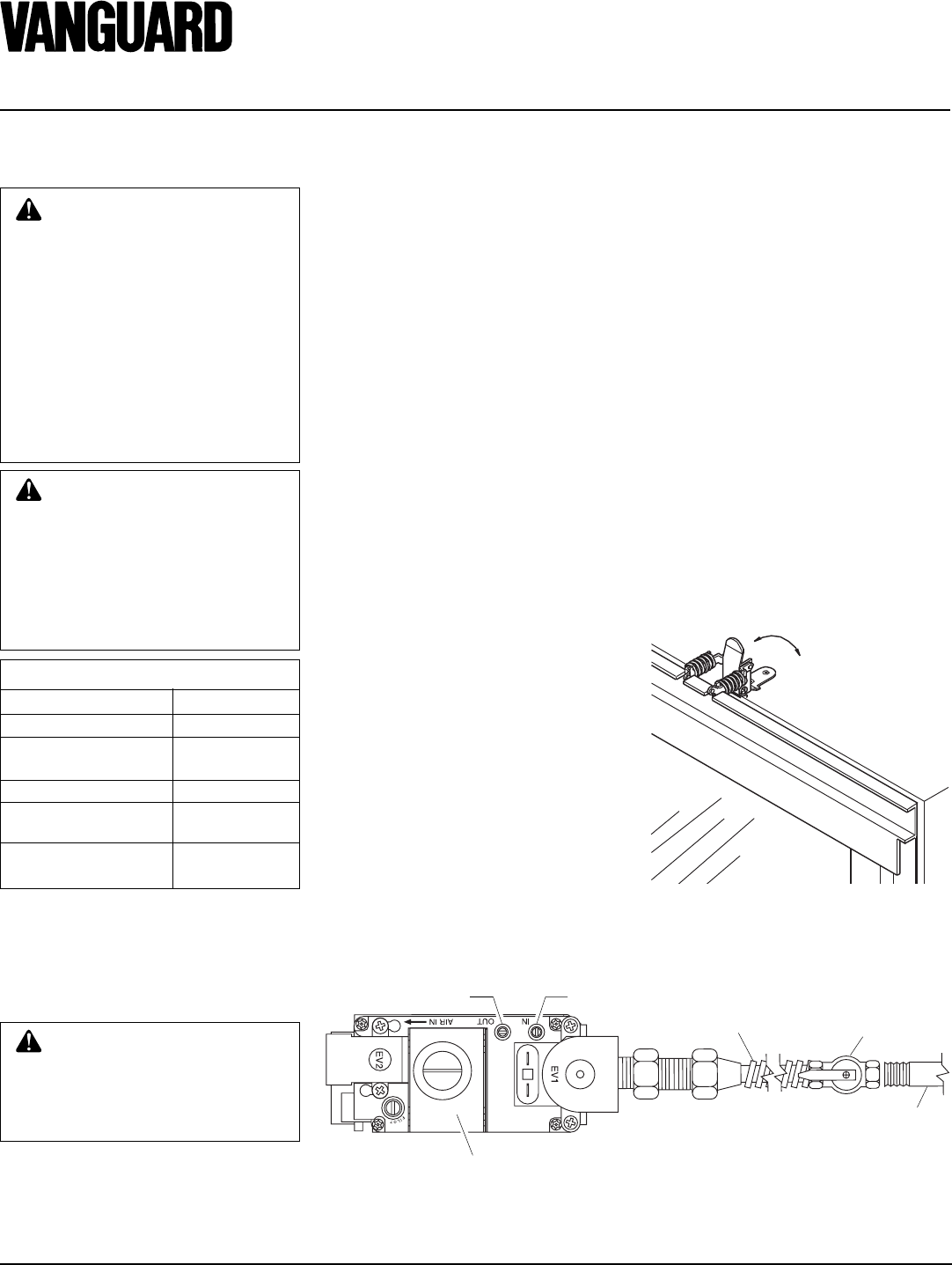

The gas control valve is secured underneath

the firebox with two brackets fastened to the

firebox bottom. Two pressure taps are pro-

vided on the gas control valve for a pressure

gauge connection (see Figure 41).

Equipment

Shutoff

Valve

Flexible Gas Line

Do NOT Kink

1/2" NPT

Incoming

Gas Line

Inlet

Pressure

Tap

Outlet

Pressure

Tap

Note:

1) Wire Connections

Not Shown for Clarity

2) * 1/8" NPT Plugged

Tapping

Figure 41 - Connecting Flexible Gas Line to Electronic Valve

Red Surface Indicates

For Propane/LP Use Only

INSTALLING LOG SET

Before proceeding, make sure the gas con-

trol valve is in the “OFF” position. Logs

have been packaged separately to prevent

damage to glass or refractory.

1. Remove top and bottom louvers by si-

multaneously pulling both top end

spring latches towards the center of the

appliance until they are disengaged from

locating holes. Repeat for bottom end

spring latches and pull outward. Reverse

procedure to install louvers back.

2. Remove the screen rod by sliding

spring clip on one end toward the cen-

ter. Slide rod into screen rod hole until

other end of rod is free. Remove rod.

3. To open the glass door, open the pairs

of latches located on the top and bottom

of the firebox (see Figure 42).

Note:

Use

caution when opening these latches.

4. Carefully open the door. The glass door

is mounted to the firebox with 5 screws.

5. To remove the logs from the shrink

wrap, carefully cut the plastic around

the perimeter of the log. Do not try to

remove the logs from the package with-

out first cutting the plastic.

6. Figure 43, page 19 shows the log set.

Logs “A” have the knot at the end of

the log. Logs “B” have the knot at the

middle of the log. Twigs “C” have the

shape of a “Y”. Twigs “D” have the

shape of bent twigs. Twig “E” is a

straight twig which is placed across the

top of Logs “B”.

7. Figure 44, page 19, shows the top view

of the burner and grate.

Open

Close

Figure 42 - Removing Glass Door

8. Place logs “A” as shown in Figure 45,

page 19.

9. Place logs “B” as shown in Figure 46,

page 19. Lift the end of log “A” that will

be propped up and place log “B” under

it. At the same time, the other side of

log “B” is placed over the other log “A”.

Repeat procedure for the other log “B”.

10. Take twigs “C” (shaped like a “Y”)

and place them as shown in Figure 47,

page 19.

11. Take twigs “D” (bent twig) and place

them as shown in Figure 47, page 19.

12. Place twig “E” across the top of logs

“B” a shown in Figure 47, page 19.

13. When finished installing the logs, close

the glass doors while making certain that

the safety door switch is fully depressed

by the door frame before securing the

four (4) spring loaded latches.

14. Replace the louvers in reverse order

with the grilles pointing in the down

position.