Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

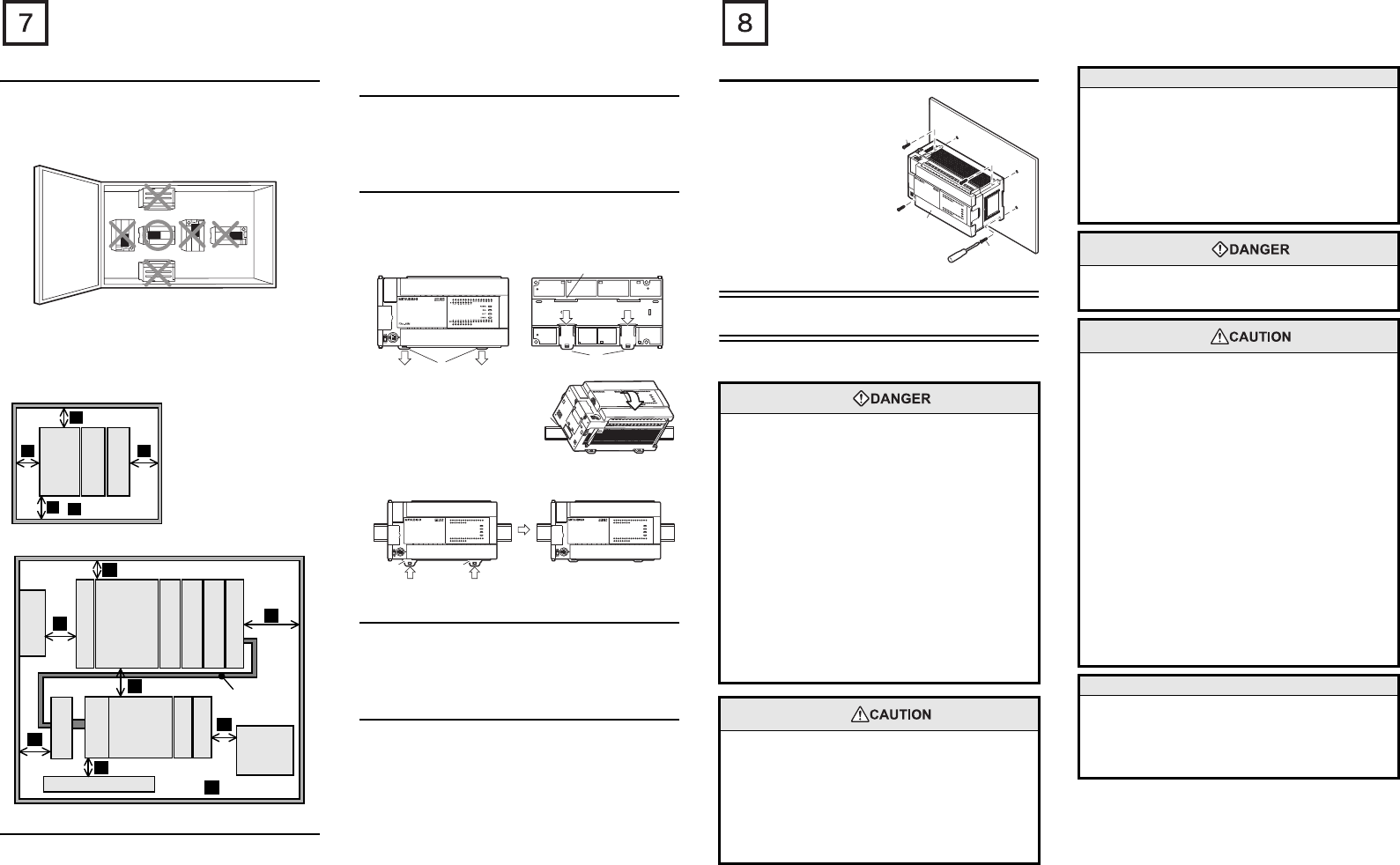

2.2 Installation location

Install the PLC in an environment conforming to the generic

specifications (section 2.1), installation precautions and notes.

For more details, refer to FX

3U

Series User's Manual - Hardware

Edition.

Installation location in enclosure

Space in enclosure

Extension devices can be connected on the left and right sides of the

main unit of the PLC.

If you intend to add extension devices in the future, keep necessary

spaces on the left and right sides.

2.2.1 Affixing The Dust Proof Sheet

The dust proof sheet should be affixed to the ventilation port before

beginning the installation and wiring work.

→ For the affixing procedure, refer to the instructions on the

dust proof sheet.

Be sure to remove the dust proof sheet when the installation and

wiring work is completed.

2.3 Procedures for installing to and detaching from

DIN rail

The products can be installed on a DIN46277 rail [35mm (1.38”)

wide]. This section explains the installations of the main units.

For the input/output extension units/blocks and special adapters,

refer to the following manual.

→ Refer to FX3U Series User’s Manual - Hardware Edition.

2.3.1 Installation

1) Connect the expansion boards and special adapters to the main

unit.

2) Push out all DIN rail mounting hooks (below fig.A)

3) Fit the upper edge of the DIN rail

mounting groove (right fig.C)

onto the DIN rail.

4) Lock the DIN rail mounting hooks (below fig.D) while pressing the

PLC against the DIN rail.

2.4 Procedures for installing directly (with M4

screws)

The product can be installed directly on the panel (with screws).

This section explains the installation of the main units.

As for the details of the installation/detaching for input extension

units/blocks and special adapters, refer to the following manual.

→ Refer to FX3U Series User's Manual - Hardware Edition.

2.4.1 Mounting hole pitches

Refer to the External Dimensions (section 1.2) for the product's

mounting hole pitch information.

As for the details of the mounting hole pitches for extension unit/

block and special adapters, refer to the following manual.

→ Refer to FX3U Series User's Manual - Hardware Edition.

≥

50mm (1.97")

A

A

A

A

A

FX

3U

Series

main

unit

FX

2N

-16EX

-ES/UL

FX

2N

-16EYT

-ESS/UL

Configuration without extension cable

Another equipment

Another

equipment

Extension

cable

·FX

0N

-65EC

·FX

0N

-30EC

Another

equipment

A

A

A

A

A

A

A

A

≥

50mm (1.97")

Configuration in 2 stages with extension cable

FX

2N

-CNV-BC

Input/output

powered

extension

unit

FX

2N

-16EX

-ES/UL

FX

2N

-10PG

FX

2N

-8AD

FX

3U

Series

main unit

FX

2N

-16EX-ES/UL

FX

2N

-16EYT-ESS/UL

FX

2N

-4AD

FX

2N

-16EYR-ES/UL

FX

3U

-4AD-ADP

A

2)2)

2)

A

2)

C

C

RUN

STOP

FX

3U

-48MR/ES

-48MR/ES

FX

3U

-48M

FX

3U

-48M

ERROR

RUN

BATT

POWER

0

3

1

2

IN

6

4

5

21

7

20

24

22

23

26

25

10

11

13

12

16

14

15

17

27

OUT

0

3

1

2

6

4

5

21

7

20

24

22

23

26

25

10

11

13

12

16

14

15

17

27

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

1011 1312 161415 17

27

0312 645

21

7

20 2422 23 2625

1011 1312 161415 17

27

Y12Y10 Y16Y14 Y22Y20 Y26COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1

COM3 Y15 Y17COM4 Y23Y25 Y27Y21

X5

X0

X1

X2

X3 X7

X11

X13

X40VS/S

N24V

X6 X10 X12X14 X16X20

L X27X23 X25X15X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

1011 1312 161415 17

27

0312 645

21

7

20

24

2223

2625

1011 1312 161415 17

27

Y12Y10 Y16Y14 Y22Y20 Y26COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1

COM3 Y15 Y17COM4 Y23Y25 Y27Y21

X5

X0

X1

X2

X3 X7

X11

X13

X40VS/S

N24V

X6 X10 X12X14 X16X20

L

X27X23 X25X15X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0 312

IN

OUT

645

21

7

20 2422 23 2625

1011 1312

12

1614 15 17

27

0 312 645

21

7

20 2422 23 2625

1011 1312

12

1614 15 17

27

Y12Y10

Y10

Y16Y14 Y22Y20 Y26COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1

COM3

COM3

Y15 Y17

Y17

COM4

COM4

Y23 Y25Y27Y21

Y21

X5

X0

X1

X2

X3 X7

X11

X13

X13

X40VS/S

N 24V

X6 X10 X12X14

X14

X16 X20

L X27X23 X25X15X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0 312

IN

OUT

645

21

7

20 2422 23 2625

1011 1312

12

1614 15 17

27

0 312 645

21

7

20 2422 23 2625

1011 1312

12

1614 15 17

27

Y12Y10

Y10

Y16Y14 Y22Y20 Y26COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1

COM3

COM3

Y15 Y17

Y17

COM4

COM4

Y23 Y25Y27Y21

Y21

X5

X0

X1

X2

X3 X7

X11

X13

X13

X40VS/S

N 24V

X6 X10 X12X14

X14

X16 X20

L X27X23 X25X15X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

1011 1312 161415 17

27

0312 645

21

7

20 2422 23 2625

1011 1312 161415 17

27

Y12Y10 Y16Y14 Y22Y20 Y26COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1

COM3 Y15 Y17COM4 Y23Y25 Y27Y21

X5

X0

X1

X2

X3 X7

X11

X13

X40VS/S

N 24V

X6 X10 X12X14 X16X20

L X27X23 X25X15X17 X21

X24 X26X22

FX

3U

-48M

ERROR

RUN

BATT

POWER

R

0312

IN

OUT

645

21

7

20 2422 23 2625

1011 1312 161415 17

27

0312 645

21

7

20 2422 23 2625

1011 1312 161415 17

27

Y12Y10 Y16Y14 Y22Y20 Y26COM5

COM1

Y24Y6

Y4Y2Y0

Y7 Y11 Y13Y5

COM2

Y3

Y1

COM3 Y15 Y17COM4 Y23Y25 Y27Y21

X5

X0

X1

X2

X3 X7

X11

X13

X40VS/S

N 24V

X6 X10 X12X14 X16X20

L

X27X23 X25X15X17 X21

X24 X26X22

D

4)

D

4)

2.4.2 Installation

1) Make mounting holes in the

mounting surface referring to

the external dimensions

diagram.

2) Fit the main unit (A in the right

figure) based on the holes, and

secure it with M4 screws (B in

the right figure).

The mounting hole pitches and

number of screws depend on

the product. Refer to the

external dimensions diagram.

3. Power supply/input/output specifications

and examples of external wiring

As for the details of the power supply wiring and input/output wiring,

refer to FX3U Series User's Manual - Hardware Edition.

DESIGN

PRECAUTIONS

• Make sure to have the following safety circuits outside of the

PLC to ensure safe system operation even during external

power supply problems or PLC failure.

Otherwise, malfunctions may cause serious accidents.

1) Most importantly, have the following: an emergency stop

circuit, a protection circuit, an interlock circuit for opposite

movements (such as normal vs. reverse rotation), and an

interlock circuit (to prevent damage to the equipment at the

upper and lower positioning limits).

2) Note that when the PLC CPU detects an error, such as a

watchdog timer error, during self-diagnosis, all outputs are

turned off. Also, when an error that cannot be detected by

the PLC CPU occurs in an input/output control block,

output control may be disabled.

External circuits and mechanisms should be designed to

ensure safe machinery operation in such a case.

3) Note that when an error occurs in a relay, triac or transistor

output device, the output could be held either on or off.

For output signals that may lead to serious accidents,

external circuits and mechanisms should be designed to

ensure safe machinery operation in such a case.

DESIGN

PRECAUTIONS

• Do not bundle the control line together with or lay it close to the

main circuit or power line. As a guideline, lay the control line at

least 100mm (3.94") or more away from the main circuit or

power line.

Noise may cause malfunctions.

• Install module so that excessive force will not be applied to the

built-in programming connectors, power connectors or I/O

connectors.

Failure to do so may result in wire damage/breakage or PLC

failure.

FX

3U

-48MFX

3U

RUN

POWER

ERROR

BATT

FX

3U

-48MFX

3U

ERROR

RUN

BATT

POWER

0

3

1

2

IN

OUT

6

4

5

21

7

20

24

22

23

26

25

10

11

13

12

16

14

15

17

27

0

3

1

2

6

4

5

21

7

20

24

22

23

2625

10

11

13

12

16

14

15

17

27

B

A

B

Notes

• Simultaneously turn on and off the power supplies of the main

unit and extension devices.

• Even if the AC power supply causes an instantaneous power

failure for less than 10 ms, the PLC can continue to operate.

• Even if the DC power supply causes an instantaneous power

failure for less than 5ms, the PLC can continue to operate.

• If a long-time power failure or an abnormal voltage drop occurs,

the PLC stops, and output is turned off. When the power

supply is restored, it will automatically restart (when the RUN

input is on).

WIRING

PRECAUTIONS

• Cut off all phases of the power supply externally before

installation or wiring work in order to avoid damage to the

product or electric shock.

WIRING

PRECAUTIONS

• Connect the AC power supply to the dedicated terminals

specified in this manual.

If an AC power supply is connected to a DC input/output

terminal or DC power supply terminal, the PLC will burn out.

• Do not wire vacant terminals externally.

Doing so may damage the product.

• Use class D grounding (grounding resistance of 100Ω or less)

with a wire of 2mm

2

or thicker on the grounding terminal of the

FX3U Series main unit.

However, do not connect the ground terminal at the same point

as a heavy electrical system.

• When drilling screw holes or wiring, make sure cutting or wire

debris does not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or

malfunctions.

• Make sure to properly wire to the terminal in accordance with

the following precautions.

Failure to do so may cause electric shock, equipment failures, a

short-circuit, wire breakage, malfunctions, or damage to the

product.

- The disposal size of the cable end should follow the

dimensions described in the manual.

- Tightening torque should follow the specifications in the

manual.

Notes

• Input/output wiring 50 to 100 m (164’1” to 328’1”) long will

cause almost no problems of noise, but, generally, the wiring

length should be less than 20 m (65’7”) to ensure the safety.

• Extension cables are easily affected by noise. Lay the cables

at a distance of at least 30 to 50 mm (1.19” to 1.97”) away from

the PLC output and other power lines.