Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

11

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE

Vertical Venting

The vent pipes must be connected to the proper collars on the unit and

the exhaust vent pipe must be connected to the termination cap or the

unit will not operate. The combustion air vent pipe can be connected to

the termination cap (see

Figure 6b) or it can terminate inside the chimney

(see

Figure 6a). The bottom opening of the chimney must be sealed

around the vent pipes if the combustion air vent is not connected to the

termination cap. Use unfaced fiberglass insulation to seal around the vent

pipes or a positive flue connection using a seal-off plate. The insulation

may give off an odor during the first hour of operation.

NOTES:

The minimum vertical rise (exhaust vent) is 10 feet (3.05 M) and the

maximum vertical rise is 35 feet (10.67 M). These dimensions are

measured from the flue collar of the unit to the end of the vent pipe,

The fireplace and fireplace chimney must be clean and in good working

order and constructed of non-combustible materials. Inspect chimney

clean-outs for proper fit and seal.

See Table 5 for the minimum vertical termination height requirements.

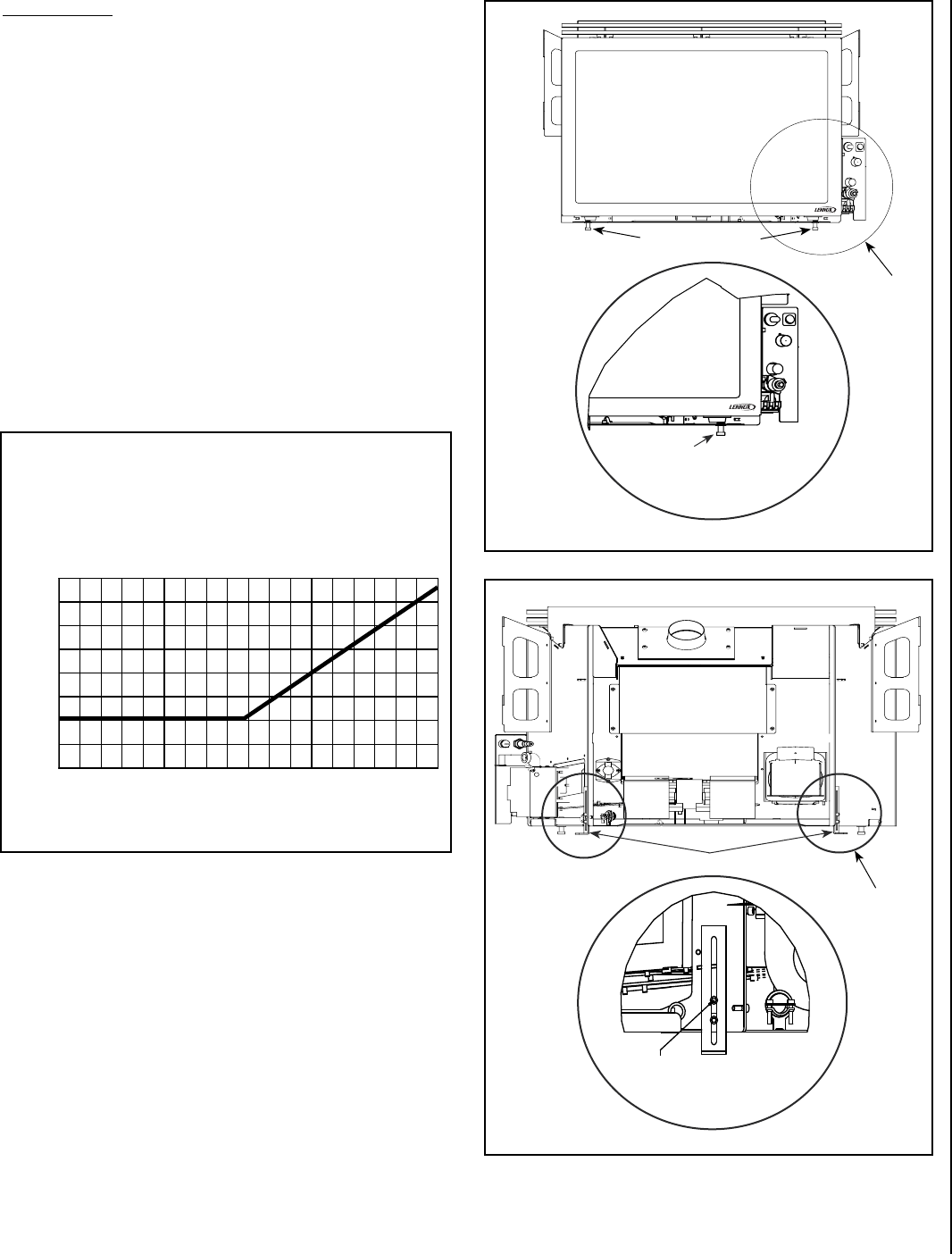

DETAIL B

Use 5/32 allen wrench to loosen

and adjust bracket up or down,

tighten when at right height

Right front leveling leg

Use open end 9/16”

wrench to adjust height

up or down

Front leveling legs

See

Detail B

Rear leveling legs

Figure 7

DETAIL B

See

Detail C

FRONT

LEVELING

LEGS

REAR

LEVELING

LEGS

Figure 8

DETAIL C

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

� � � � � � � � � � � � � � � � � �

Vertical Termination Height Minimum

(Factory Built and Masonry Fireplaces)

The vent/air intake termination clearances above the high side of an

angled roof is as follows:

8 (2.4)

7 (2.1)

6 (1.8)

5 (1.5)

4 (1.2)

3 (0.9)

2 (0.6)

1 (0.3)

0 (0.0)

2/12

4/12

6/12

8/12

10/12

12/12

14/12

16/12

Table 5

Feet (meters)

Roof Pitch

Insert Leveling

At each front and rear corner of the insert is an adjustable leg provided

to level the insert should the hearth of the fireplace be uneven. To adjust

the legs in the rear, loosen the two 5/32” allen head screws, move the leg

to the desired height, and then tighten the screws. Repeat these steps

for each adjusting leg. To adjust the legs in the front use a 9/16” open

end wrench. See

Figures 7 and 8.