Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

Part # 4526884 Rev 4 (10/08/10)Page 12

INSTALLATION continued

Appliances Equipped with Casters:

1. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69 or latest edition, addenda

Z21.69a-1989, and a quick-disconnect device that

complies with the Standard for Quick Disconnects for Use

with Gas Fuel. ANSI Z21.41 or latest edition.

2. The front casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick-disconnect

device or its associated piping.

3. Please be aware; required restraint is attached to a

bracket (which is located on the rear caster closest to the

gas connection), and if disconnection of the restraint

is necessary; be sure to reconnect the device after the

appliance has been returned to its original position.

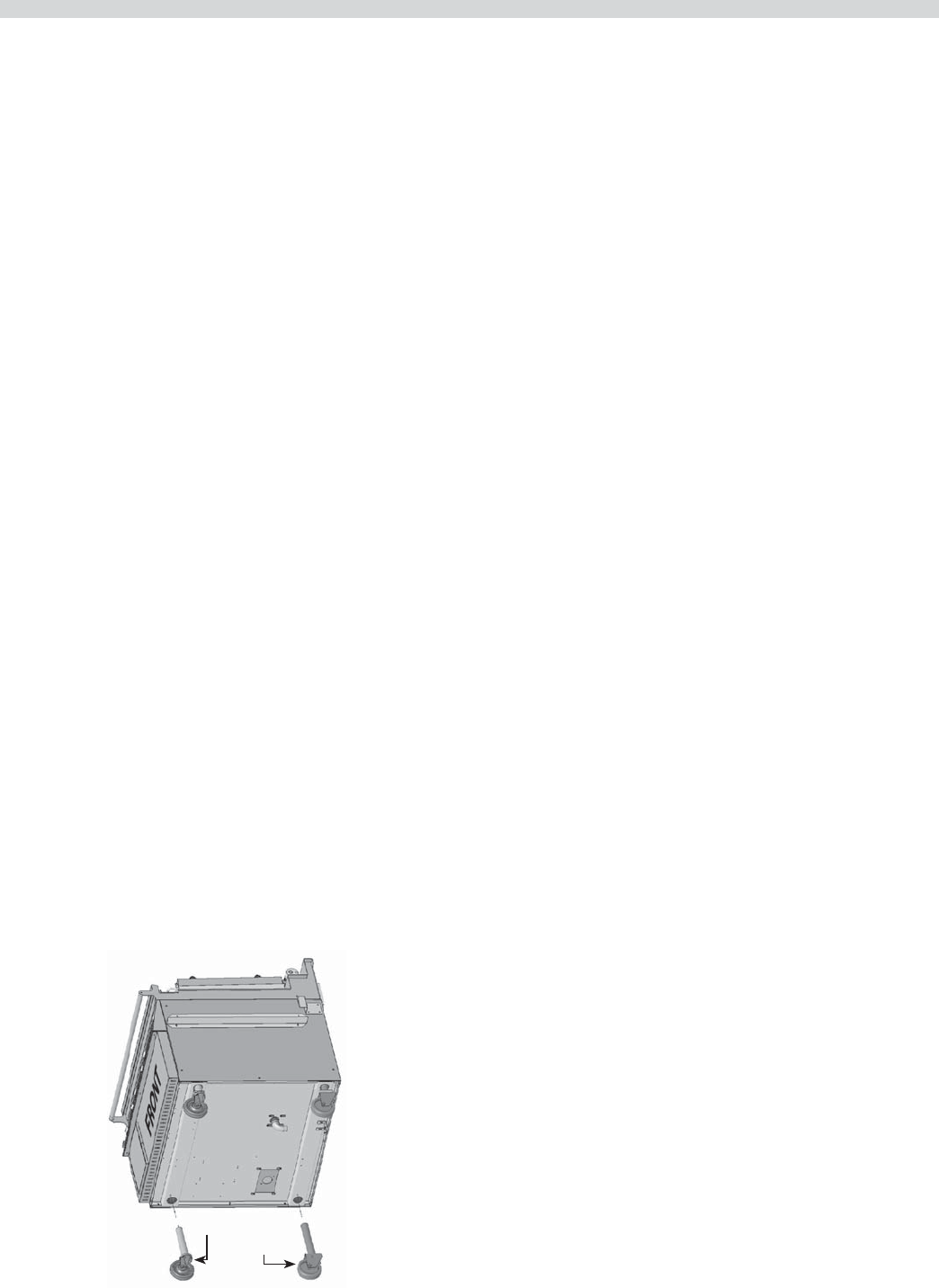

Swivel Caster Installation

Prior to installation, the four casters, supplied loose with the

grill, must be securely located on the underside of the base.

The casters tted with a brake must be located at the front of

the grill.

1. Carefully remove the top and side packaging leaving the

grill on shipping pallet.

DO NOT REMOVE THE TIES SECURING THE PLATEN ARMS

TO THE GRILL TOWEL BAR.

2. Raise the grill vertically o the pallet to a comfortable

working height and install the casters. DO NOT TIP THE

GRILL ON ITS BACK OR SIDE. If a truck lift is used, be

careful when inserting the lifting arms under the grill as

the gas inlet elbow is protruding in the center of the base.

WARNING - GRILL WEIGHT IS APPROXIMATELY 800 LBS –

USE CAUTION

3. Install the casters as shown below. The two casters with

brakes go on the front, and the two without on the rear.

WITH

BRAKE

WITHOUT

BRAKE

NOTE: CASTERS MUST BE THREADED INTO GRILL BASE

LEAVING APPROXIMATELY ONE INCH OF EXPOSED

THREAD. THIS IS THE STARTING POINT FOR LEVELLING THE

GRILL AFTER IT IS IN POSITION.

Ventilation and Clearance:

One of the most important considerations for e cient grill

operation is proper ventilation and air supply. Insure the

grill is installed so the products of combustion are removed

e ciently and the ventilation system does not produce

drafts that interfere with proper burner operation.

Proper operation of exhaust fans (speed, rotation and

adjustment) is essential. In addition to the exhaust system

the make-up air system, (HVAC), for the kitchen is the

air supply for the combustion air for the burners. Proper

incoming air is essential for all gas operated equipment. Poor

incoming make-up will cause ine cient burner operation,

delayed ignition and possible burner failure.

Any ventilation system will break down if improperly

maintained. The duct system, the hood, and the lters must

be cleaned on a regular basis and kept grease free.

The room containing the grill is required to have a

permanent air vent. The minimum e ective area of the vent

shall be 0.7 in.² per kW. Air vents shall be of such a size to

compensate for the e ects of any extract fan in the premises.

Changing to a di erent type of gas

Changing from one gas type to another must only be

done by a Quali ed Gas Engineer and according to local

regulations.