Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

105706-01B

For more information, visit www.desatech.com

For more information, visit www.desatech.com

19

19

GAS SUPPLY TESTING

Note:

This section is intended as a guide for qualified service

technicians installing gas to the appliance.

CAUTION: Do not connect appliance before pres-

sure testing gas piping. Damage to the gas valve may

result and an unsafe condition may be caused.

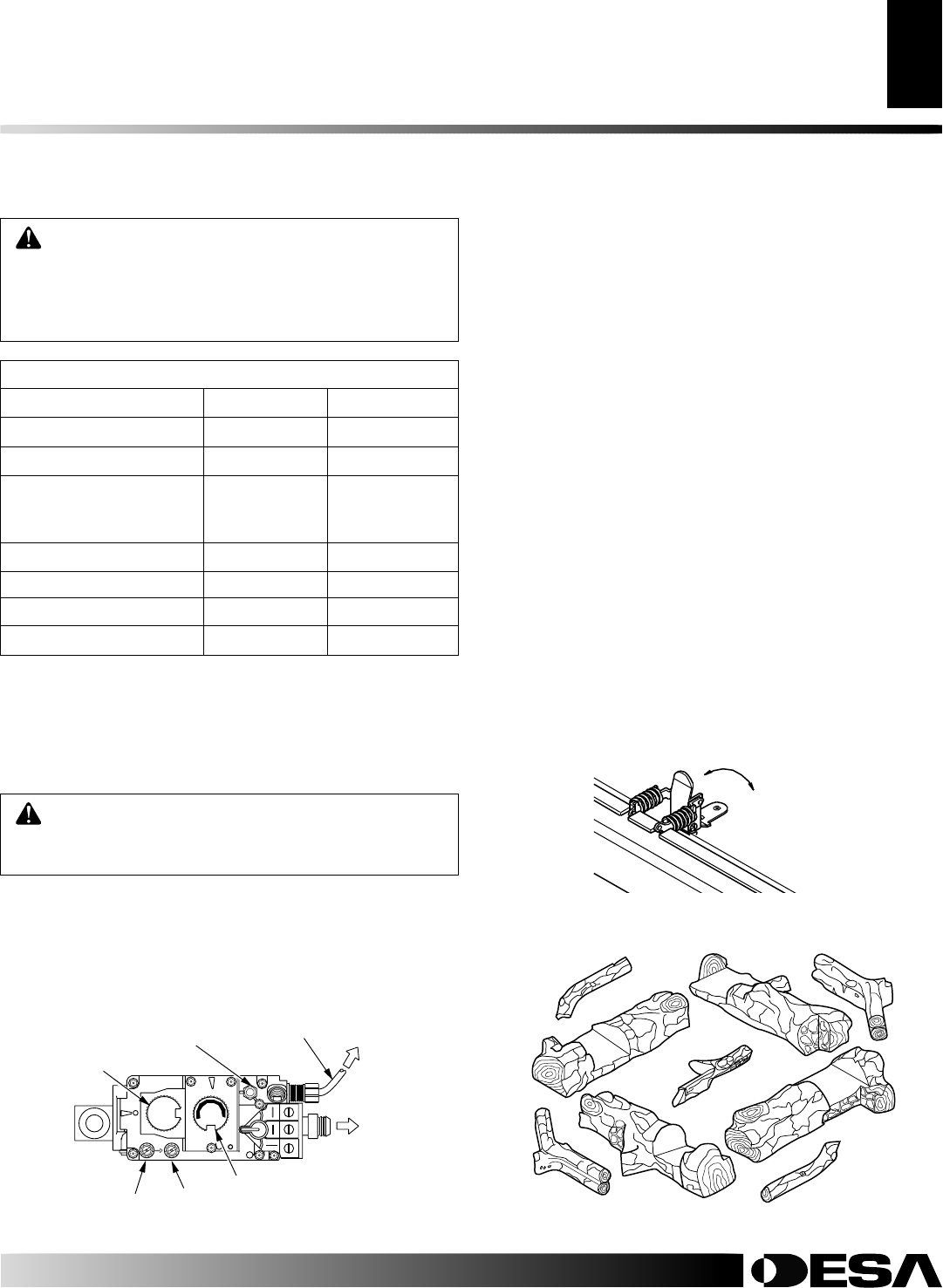

The millivolt system with a manual HI/LO applies only to the

VDVF36STN/STP and VDVF36PN/PP models. The gas control

valve is secured underneath the firebox with two brackets fastened

to the firebox bottom. Two pressure taps are provided on the gas

control valve for a pressure gauge connection (see Figure 40).

O

F

F

P

I

L

O

T

O

N

L

O

H

I

P

I

L

O

T

EA

16AI

7

TPTH TP TH

Figure 40 - Millivolt Control Valve

Pilot Adjustment Cap

ON/OFF

Knob

Outlet

Pressure

Inlet Pressure

INSTALLATION

Continued

WARNING: Improper installation, adjustment, al-

teration, service, or maintenance can cause injury or

property damage. Refer to this manual. For assis-

tance or additional information, consult a qualified

installer, service agency, or gas supplier.

GAS RATING

TYPE OF GAS NATURAL PROPANE/LP

Max. Input Rating: 30,000 Btu/hr 28,000 Btu/hr

Orifice Size (0-4,500 Ft.): 7/64" #52

Min. Input Rating: 21,000 Btu/hr 20,000 Btu/hr

(When the Valve is in

the LOW Position)

* Max. Output Rating: 21,000 Btu/hr 20,000 Btu/hr

Manifold Pressure: 3.5 in. WC 10.0 in. WC

**Min. Supply Pressure: 4.5 in. WC 11.0 in. WC

**Max. Supply Pressure: 10.5 in. WC 13.0 in. WC

* 70% Efficiency (flue loss calculation).

* For the purpose of input adjustment.

INSTALLATION

Gas Line Hook-Up (Cont.)

Gas Supply Testing

Installing Log Set

Pilot Gas Line -

Do Not Kink

To Pilot

Burner

To Main Burner

Flame Adjustment Knob

INSTALLING LOG SET

Before proceeding, make sure the gas control valve is in the “OFF”

position. Logs have been packaged separately to prevent damage to

glass or refractory.

1. Remove top and bottom louvers by simultaneously pulling both

top end spring latches towards the center of the appliance until

they are disengaged from locating holes. Repeat for bottom end

spring latches and pull outward. Reverse procedure to install

louvers back.

2. Remove the screen rod by sliding spring clip on one end to-

ward the center. Slide rod into screen rod hole until other end

of rod is free. Remove rod.

3. To open the glass door, open the pairs of latches located on the

top and bottom of the firebox (see Figure 41).

Note:

Use cau-

tion when opening these latches.

4. Carefully open the door. The glass door is mounted to the fire-

box with 5 screws.

5. To remove the logs from the shrink wrap, carefully cut the

plastic around the perimeter of the log. Do not try to remove

the logs from the package without first cutting the plastic.

6. Figure 42 shows the log set. Logs “A” have the knot at the end

of the log. Logs “B” have the knot at the middle of the log.

Twigs “C” have the shape of a “Y”. Twigs “D” have the shape

of bent twigs. Twig “E” is a straight twig which is placed across

the top of Logs “B”.

Open

Close

Figure 41 - Opening Door Latches

Figure 42 - Log Set (9 Pieces)

A

A

B

B

C

C

D

D

E