Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

K-40

4.

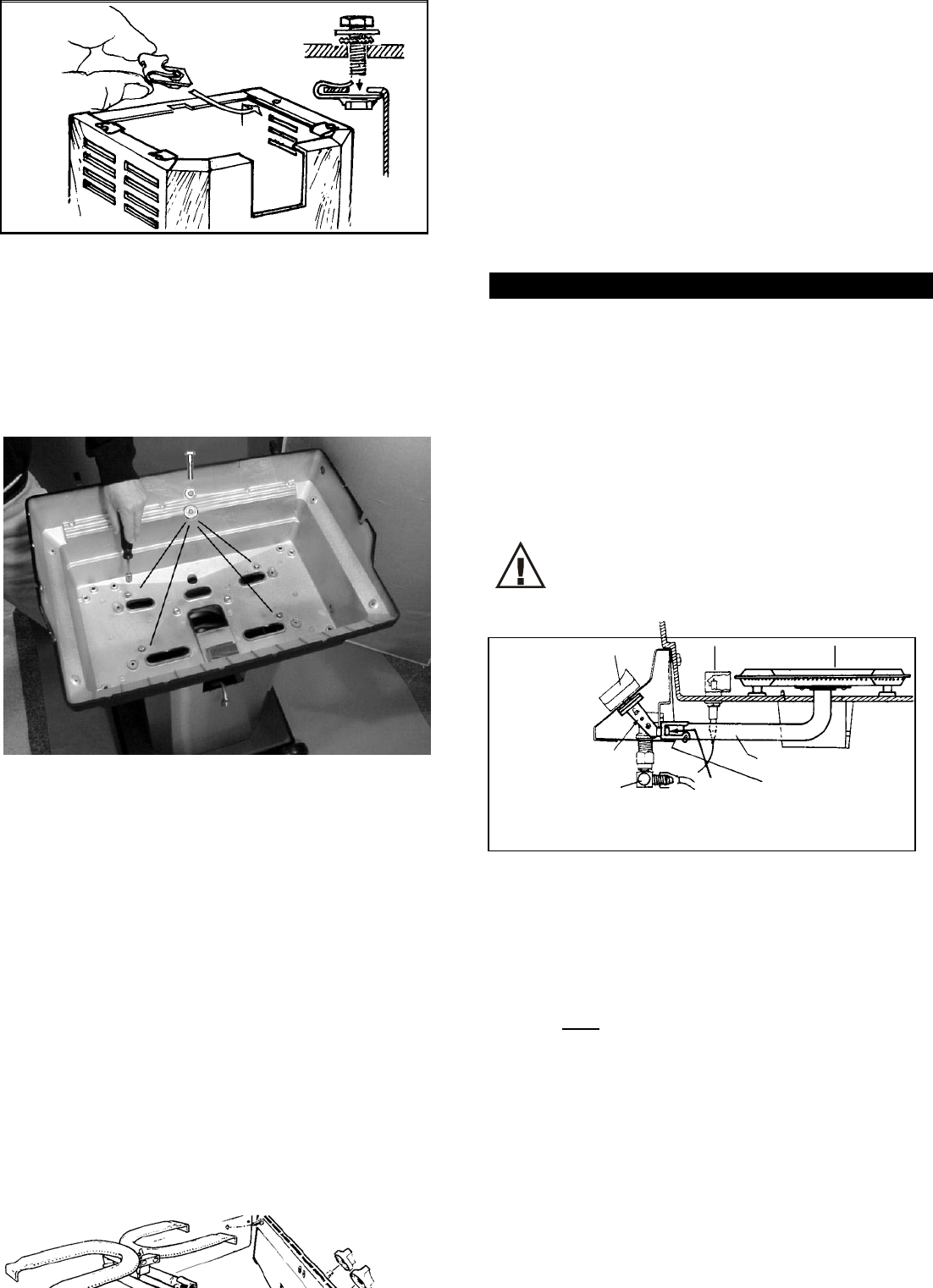

Figure 6 Control Panel/ Feedline to Valve Connection

Figure 4 Installation of Cage Nuts on Pedestal

ORIFICE ENGAGEMENT

4. Place lower grill casting on top of pedestal lining

up four bolt holes (located just above air vents) with

cage nuts just installed (see Fig. 5). Then insert the 4-

1/4" X 20" X 1 1/4" hex bolt each with a 1/4" flat

washer and 1/4" lock washer. When all four are in

place, tighten bolts securely.

At the end of each valve there is a tiny gas opening

known as an orifice. Gas exits the orifice and enters

the venturis where it mixes with air. The proper

mixture of gas and air produces a clean blue flame

with slight yellow tips from the burner.

BE CERTAIN THAT ORIFICES ARE ENGAGED

INTO THE BURNER VENTURIS (see Fig. 7). Proper

orifice engagement should be 1/4" to 3/8" into the

venturis.

FAILURE TO PROPERLY ALIGN THIS

CONNECTION MAY CAUSE A FIRE AND

RESULT IN DAMAGE TO YOUR GRILL.

K-30

CONTROL COLLECTOR BOX BURNER

KNOB

VALVE VENTURI

Figure 5 Placement Holes in Lower Grill Casting for

Hex Bolts

GAS VALVE AIR

LINE IN ORIFICE SHUTTER

5. Install burner assembly into lower casting by

inserting venturi tubes through lower casting (see

Figure 7 Proper orifice engagement

Fig. 6). The burner has a spring clip to secure the

burner in the casting. Be sure that the burner "snaps"

into position.

7. Insert feed line through the rear of the pedestal

with the bent end coming through to the front of the

pedestal. Attach 3/8" female brass flare nut to valve

assembly.

6. Attach control panel to grill head. You will note

that both of the bolts attached to the control panel

have two nuts on them. Remove plastic thread

protectors at the end of bolts and discard. Remove

the top nut leaving the remaining nut (closest to the

back of the control panel) to act as a spacer. Insert

3/4" bolts (pre-assembled on control panel) through

holes on front of lower casting. Be sure you line up

the venturis over the valve stems protruding from the

back of the control panel (see Orifice Engagement).

NOTE: BE CAREFUL NOT TO CROSS THREAD

THIS FITTING. This is a brass to brass flared fitting,

IT WILL NOT

REQUIRE ADDED SEALANT OR

TEFLON TAPE. Once properly in place, tighten both

control panel and feedline securely.

Attach nuts and leave slightly loose at this time to

allow for adjustment (see Fig. 6). If the venturis do

not align over the valve stems properly, they can

be rotated slightly for proper adjustment.

16