Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

18

115 VOLT LINE CONNECTION OF ACCESSORIES (HUMIDIFIER

AND

E LECTRONIC A IR C LEANER)

WARNING

T

O AVOID PERSONAL INJURY, ELECTRICAL SHOCK OR DEATH, DISCONNECT

ELECTRICAL POWER BEFORE SERVICING OR CHANGING ANY ELECTRICAL

WIRING.

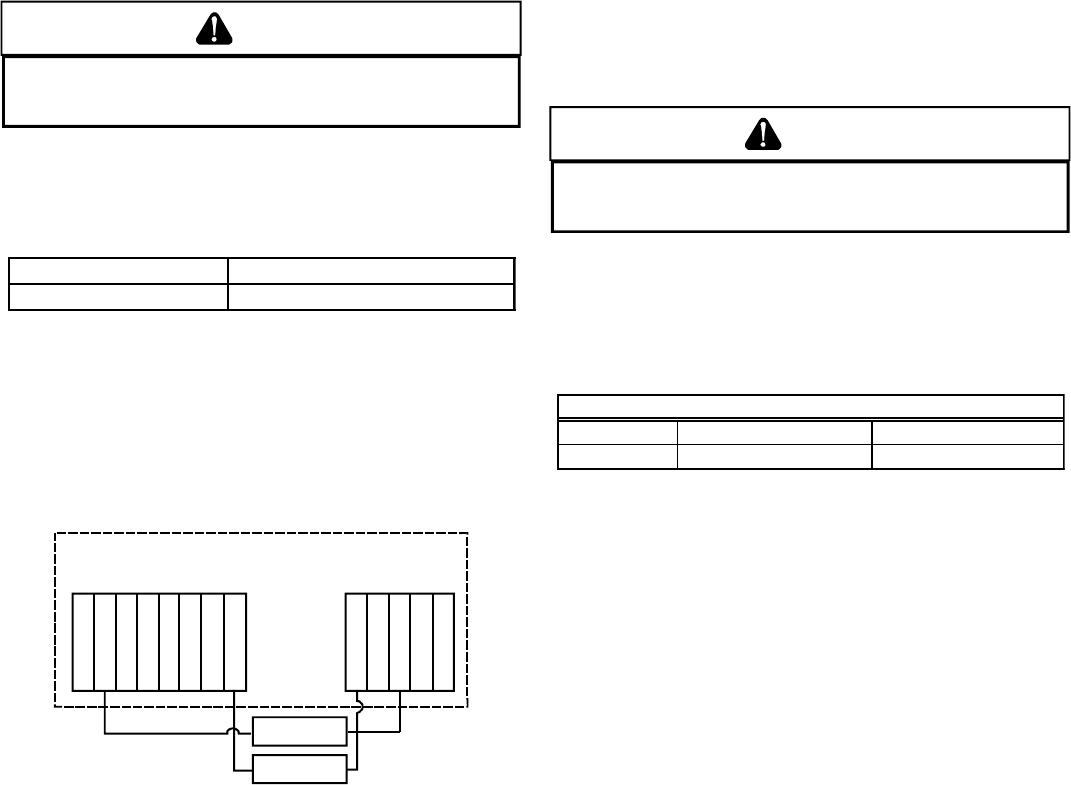

The furnace integrated control module is equipped with line voltage

accessory terminals for controlling power to an optional field-

supplied humidifier and/or electronic air cleaner.

The accessory load specifications are as follows:

Humidifier 1.0 Amp maximum at 120 VAC

Electronic Air Cleaner 1.0 Amp maximum at 120 VAC

Turn OFF power to the furnace before installing any accessories.

Follow the humidifier or air cleaner manufacturers’ instructions

for locating, mounting, grounding, and controlling these

accessories. Accessory wiring connections are to be made

through the 1/4" quick connect terminals provided on the furnace

integrated control module. The humidifier and electronic air

cleaner hot and neutral terminals are identified as HUM and EAC.

All field wiring must conform to applicable codes. Connections

should be made as shown in the following illustration.

EAC

Line

Transformer

Hum

Line

Transformer

EAC

Hum

Air Cleaner

Humidifier

Control Module

Hot 120 VAC

Neutral 120 VAC

Optional

Accessories

{

Figure 15 - Accessories Wiring

If it is necessary for the installer to supply additional line voltage

wiring to the inside of the furnace, the wiring must conform to all

local codes, and have a minimum temperature rating of 105°C.

All line voltage wire splices must be made inside the furnace

junction box.

The integrated control module humidifier terminals (HUM) are

energized with 115 volts whenever the induced draft blower is

energized. The integrated control module electronic air cleaner

terminals (EAC) are energized with 115 volts whenever the

circulator blower is energized.

24 VAC HUM

1. 24 VAC Hum - A ¼” insulated male quick connect terminal

on the pressure switch provides 24 VAC humidifier control.

this terminal will be powered any time the pressure switch

is closed. To connect 24 VAC hum, connect 24vac line of

humidifier to piggyback on the pressure switch. The com

side of the humidfier to C on the terminal strip on the control

board (or to com side to 24VAC transformer). Do not

connect 115V humidifier to these terminals.

IX. GAS SUPPLY AND PIPING

GENERAL

The furnace rating plate includes the approved furnace gas input

rating and gas types. The furnace must be equipped to operate

on the type of gas applied. This includes any conversion kits

required for alternate fuels and/or high altitude.

CAUTION

T

O PREVENT UNRELIABLE OPERATION OR EQUIPMENT DAMAGE, THE INLET

GAS SUPPLY PRESSURE MUST BE AS SPECIFIED ON THE UNIT RATING PLATE

WITH ALL OTHER HOUSEHOLD GAS FIRED APPLIANCES OPERATING.

Inlet gas supply pressures must be maintained within the ranges

specified in the following table. The supply pressure must be

constant and available with all other household gas fired

appliances operating. The minimum gas supply pressure must

be maintained to prevent unreliable ignition. The maximum must

not be exceeded to prevent unit overfiring.

Natural Gas

Minimum: 5.0" w.c. Maximum:10.0" w.c.

Propane Gas

Minimum: 11.0" w.c. Maximum:13.0" w.c.

Inlet Gas Supply Pressure

NOTE: Adjusting the minimum supply pressure below the limits

in the above table could lead to unreliable ignition. Gas input to

the burners must not exceed the rated input shown on the rating

plate. Overfiring of the furnace can result in premature heat

exchanger failure. Gas pressures in excess of 13 inches water

column can also cause permanent damage to the gas valve.

At all altitudes, the manifold pressure must be within 0.3 inches

w.c. of that listed in the Product Data Book applicable to your

model* for the fuel used. At all altitudes and with either fuel, the air

temperature rise must be within the range listed on the furnace

nameplate. Should this appliance be converted to LP, refer to the

instructions included in the factory authorized LP conversion kit

LPT-03B .

HIGH A LTITUDE D ERATE

IMPORTANT NOTE: The furnace will naturally derate itself with

altitude. Do not attempt to increase the firing rate by changing

orifices or increasing the manifold pressure. This can cause poor

combustion and equipment failure.

When this furnace is installed at high altitude, the appropriate

High Altitude orifice kit must be applied. The furnace is supplied

with orifices sized for natural gas at altitudes up to 4,500 feet

using a heating value of approximately 1,000 Btu/hr, and should

not normally require change. Most cases will not require a change

at altitudes up to 7,500 feet. For use at altitudes in excess of 4,500

feet, refer to the following table for maximum input rates based on

altitude. Contact your local gas utility for the heating value of the

gas. Refer to the National Fuel Gas Code ANSI Z223.1 and the

following section to calculate firing rates.