Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

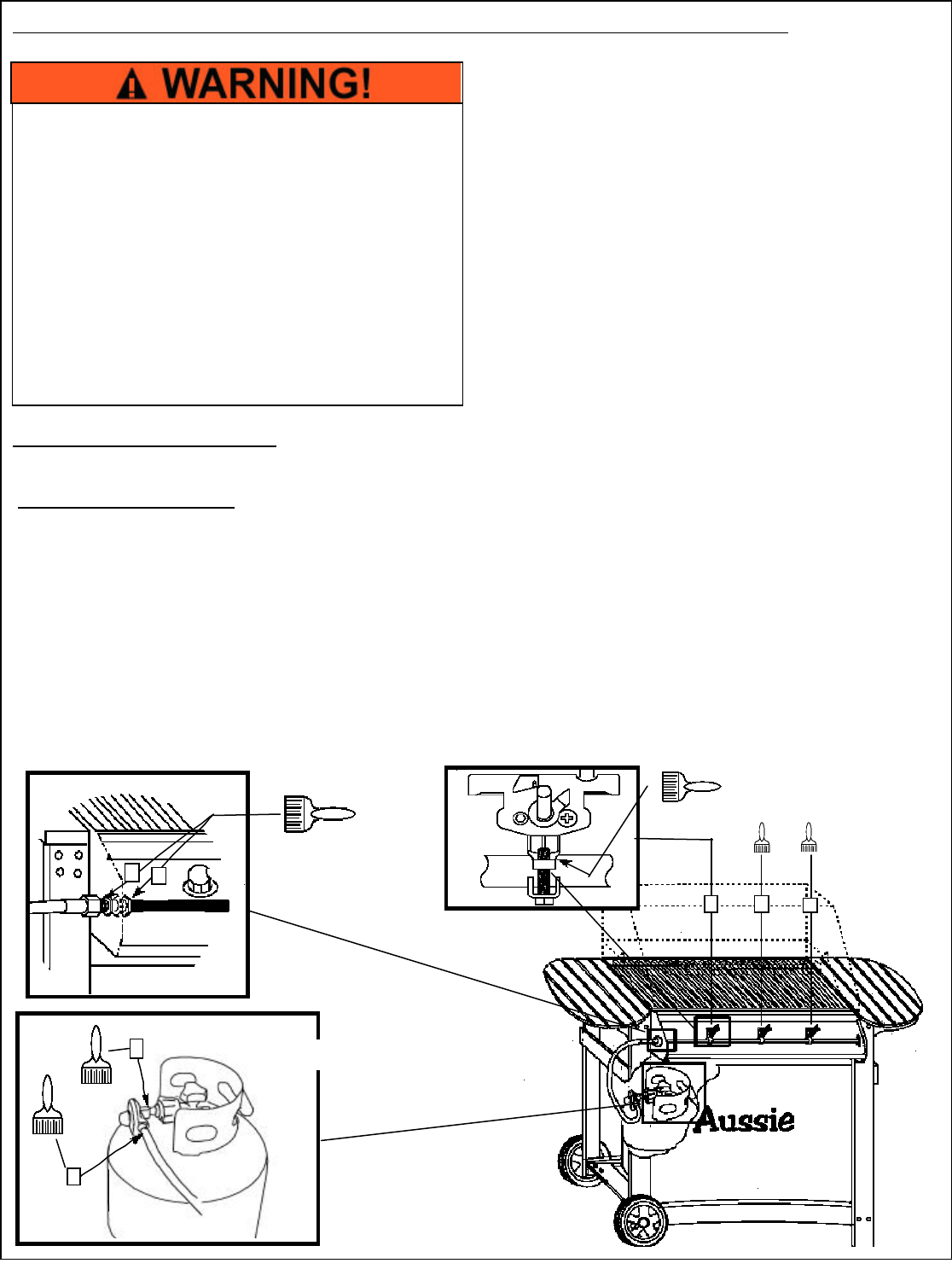

STEP 15-LEAK TESTING (TO BE PERFORMED IN A WELL-VENTILATED AREA.)

Supplies Needed for a Leak Test

Clean paint brush, water, and dishwashing liquid

How to perform a leak test

WARNING! Never use an open flame to test for gas

leaks.

1) Mix one cup of water with one cup of dish washing

liquid.

2) Confirm that all control knobs on the control panel are

in the off position.

3) Remove control knobs and the three retaining screws at

the bottom of the control panel.

4) Remove front control panel cover.

5) Open valve on LP gas cylinder (Turn counter-

clockwise).

6) Check for leaks by brushing the soap solution on all LP

gas connections and fittings. Make sure you

generously brush the seven locations with the soap

solution, completely surrounding the connections and

fittings (See diagram below.)

7) If “growing” bubbles appear on any of the connection

points, then you have detected a gas leak. Immediately

close the LP cylinder valve.

A) If leak appears at either end of hose and regulator

assembly, retighten the connection at the leak, but

do not overtighten. (Note: Only hand tighten at

coupling nut) (See Step 10 of Assembly

Instructions) Repeat Leak Test.

B) If the leak is coming from the LP gas cylinder, from

the valves at the control knobs, or if the leak cannot

be stopped, do not use the grill. Call Customer

Service at 1-800-251-7558.

8) Always turn off LP cylinder valve after performing a leak

test. (Turn clockwise to a full stop.)

9) If your LP gas grill has been in storage or has not been

used for a period of time, the burners should be

maintained. See Burner Maintenance in the Care and

Maintenance section of this manual.

· Perform a leak test before each use.

· Leak test must be performed in a well ventilated

area.

· Never perform a leak test on a grill while in use

or hot.

· If you detect a gas leak that cannot be corrected by

using the leak test procedures below, do not use

the LP gas grill.

· Never smoke or have an open flame near the grill

during a leak test.

· Insure Regulator Hose does not contact hot metal

surfaces.

24

3

4

3-THREADED FITTING

4-HOSE CONNECTION

2

1

1-MANIFOLD TUBE

2-REGULATOR HOSE FITTING

5, 6, 7 -GASKET SEAL

AROUND MANIFOLD TUBE

5

6

7