Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

Buy Weber Grill Parts. It couldn't be easier. Find your Weber parts here.

3

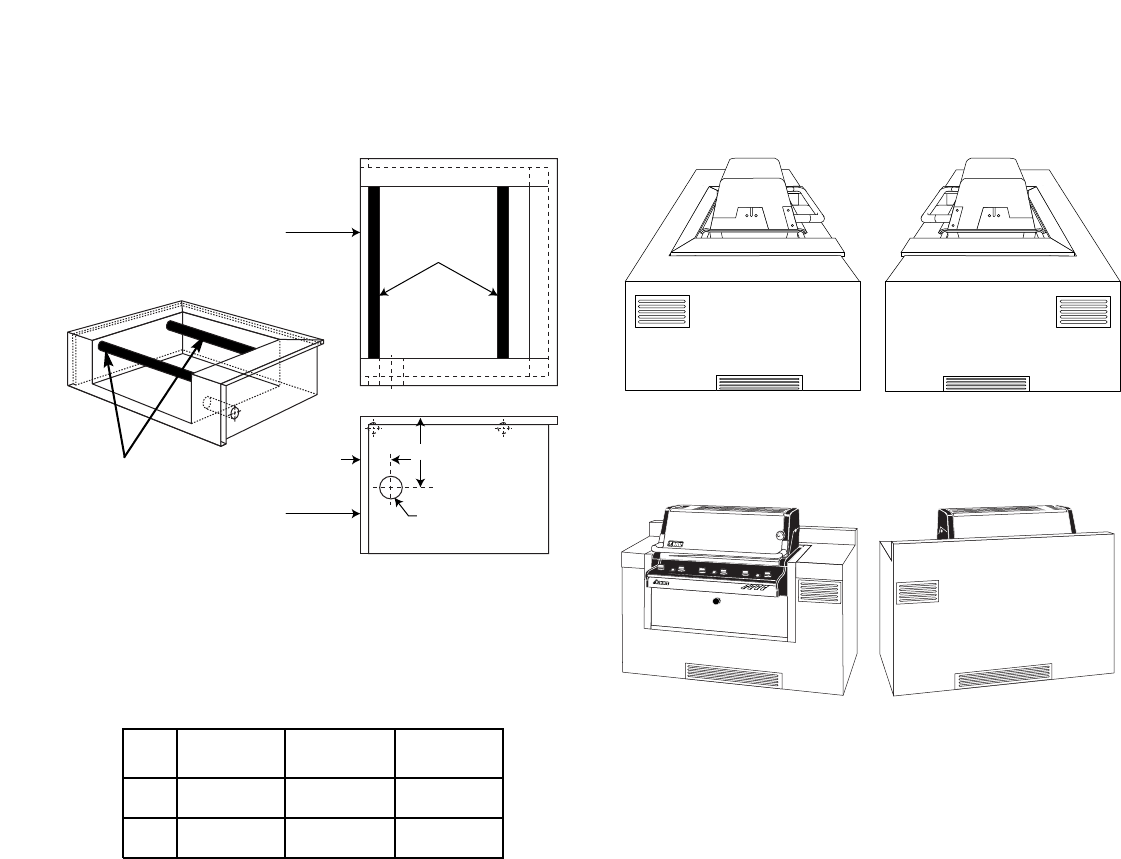

BUILT-IN SLEEVE GAS

LINE LOCATIONS

A

B

C

Support tubes

Front of sleeve

Front of sleeve

Plan view

Right side view

475 675 Tolerances

A 5.0” 5.0”

B 10.1” 10.1”

C 2.5” 2.5”

DIMENSIONS

+

1

⁄16

-

1

⁄16

+

1

⁄16

-

1

⁄16

+

1

⁄32

-

1

⁄32

BUILT-IN SLEEVE GAS LINE

LOCATIONS

The dimensions shown indicate the location of the gas

line inlet flange in the insulated sleeve. The support

members of the built-in structure must not impede

passage of the gas lines.

Area should be kept clear of sharp, jagged, or extremely

abrasive surfaces to avoid possible damage to gas supply

lines. Exercise caution when pulling gas lines through

built-in structure.

Note: Leave an access in the structure for gas supply

and regulator service.

Figure 6

Support tubes

■ Cross ventilation must be incorporated in the

supporting structure. We recommend a minimum of

100 square inches of venting per side.

■ Vents should be on two sides of the structure.

Figures 5 and 6 are references only.

■ Location of the vents should be from the center,

outward.

■ Locate the vents at both the bottom of the structure

and at the top of the structure.

■ The bottom vents should be as close to ground level

as possible. Make sure the vent area is not blocked

by interior supports of the structure.

■ We recommend vents with screens.

■ Access doors to the structure are not considered vents.

■ Clean the vents periodically.

ƽDANGER: Failure to follow recommended minimum

venting instructions can cause gas to collect in the

structure in the event of a gas leak.This may result in

a fire or an explosion which can cause serious bodily

injury or death, and damage to property.

Note: These drawings are only a reference.

VENTILATION

View of left side View of right side

View of front side View of back side

Figure 7

Figure 8