Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

6

W415-0665 / B / 02.11.08

VENTING

For safe and proper operation of the fireplace follow the venting

instruction exactly.

Deviation from the minimum vertical vent length can create

difficulty in burner start-up and/or carboning.

Provide a means for visually checking the vent connection to the

fireplace after the fireplace is installed.

Vent lengths that pass through unheated spaces (attics, garages,

crawl spaces) should be insulated with the insulation wrapped in

a protective sleeve to minimize condensation.

Use only Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp or

A

merican Metal Amerivent venting components.

Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp and

A

merican Metal Amerivent venting systems must not be

combined.

Follow the installation procedure provided with the venting

components.

For vent systems that provide seals on the inner exhaust flue,

only the outer air intake joints must be sealed using a red high

temperature silicone (RTV). This same sealant maybe used on

both the inner exhaust and outer intake vent pipe joints of all

other approved vent systems except for the exhaust vent pipe

connection to the fireplace flue collar which must be sealed using

the black high temperature sealant MillPac. A starter adaptor

must be used and may be purchased from the corresponding

supplier:

Supplier 4 / 7

Duravent W175-0053

A

merivent 4DSC-N2

Direct Temp 4DT-AAN

For Simpson Dura-Vent, Selkirk Direct Temp and American Metal

A

merivent, follow the installation procedure found on the website

for your venting supplier:

VENTING SUPPLIER WEBSITE ADDRESS

Simpson Dura-Vent www.duravent.com

Selkirk Direct Temp www.selkirkcorp.com

A

merican Metal Amerivent www.americanmetalproducts.com

When using Napoleon® venting components, use only approved

Wolf Steel Ltd. rigid / flexible vent components with the following

termination kits: wall terminal kit GD222 and GD222R, or 1/12 to

7/12 pitch roof terminal kit GD110, 8/12 to 12/12 roof terminal kit

GD111, flat roof terminal kit GD112 or periscope kit GD201 (for

wall penetration below grade). With flexible venting, in conjunction

with the various terminations, use either the 5 foot vent kit GD220

or the 10 foot vent kit GD330. These vent kits allow for either

horizontal or vertical venting of the fireplace.

The maximum number of allowable 4” vent connections is three

horizontally or vertically (excluding the fireplace and the air

terminal connections).

For optimum flame appearance and fireplace performance, keep

the vent length and number of elbows to a minimum.

Under extreme vent configurations, allow several minutes (5-15)

for the flame to stabilize after ignition.

The air terminal must remain unobstructed at all times. Examine

the air terminal at least once a year to verify that it is unobstructed

and undamaged.

Horizontal runs may have a 0” rise per foot in all cases using Wolf

Steel, Simpson Dura-Vent, Selkirk Direct Temp, or American

Metal Amerivent rigid vent components and Wolf Steel flexible

vent components.

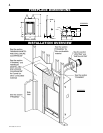

VENT LENGTHS

For optimum performance, it is recommended that horizontal runs

have a minimum 1/4” rise per foot when using Wolf Steel,

Simpson Dura-Vent, Selkirk Direct Temp, or American Metal

Amerivent rigid vent components and a minimum of 1” rise per

foot when using Wolf Steel flexible vent components.

When venting, the horizontal run must be kept to a maximum of

20 feet. If a 20 foot horizontal run is required, the fireplace must

have a minimum vertical rise immediately off the fireplace of 57”.

When terminating vertically, the vertical rise is a minimum 3 feet

and a maximum 40 feet above the fireplace.

16”

MINIMUM

24” MAXIMUM

10”

MINIMUM

56”

PLUS RISE*

12” MINIMUM

30”

MINIMUM

MAXIMUM 10 FOOT VENT LENGTH

CAN BE USED WITH GD201 PERISCOPE KIT

* REFER TO “VENTING” SECTION

INSULATION

SLEEVE

40 FEET

MAXIMUM

3 FEET

MINIMUM

* FIRST

2 FEET

REQUIRES

INSULATION

SLEEVE

FIGURES 3a-b

FIGURE 4

* The fi rst 2 feet of outer 7 “ diameter vent pipe from the appliance

must be wrapped in the 1” thick insulation sleeve (supplied).

Make sure the insulation is pulled down tight to the fi replace

when installed. There after, a 2” clearance all around the vent

pipe from combustible materials on all horizontal vent sections

is required.

!

WARNING

HORIZONTAL VENT SECTIONS: A minimum clearance of 2” all around

the vent pipe on all horizontal runs to combustibles is required. Use

fi restop spacer W010-1799 (supplied).

VERTICAL VENT SECTIONS: A minimum of 1” all around the vent pipe

on all vertical runs to combustibles is required except for clearances in

fi replace enclosures. Use fi restop spacer W500-0096 (not supplied).