Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

26

W415-0665 / B / 02.11.08

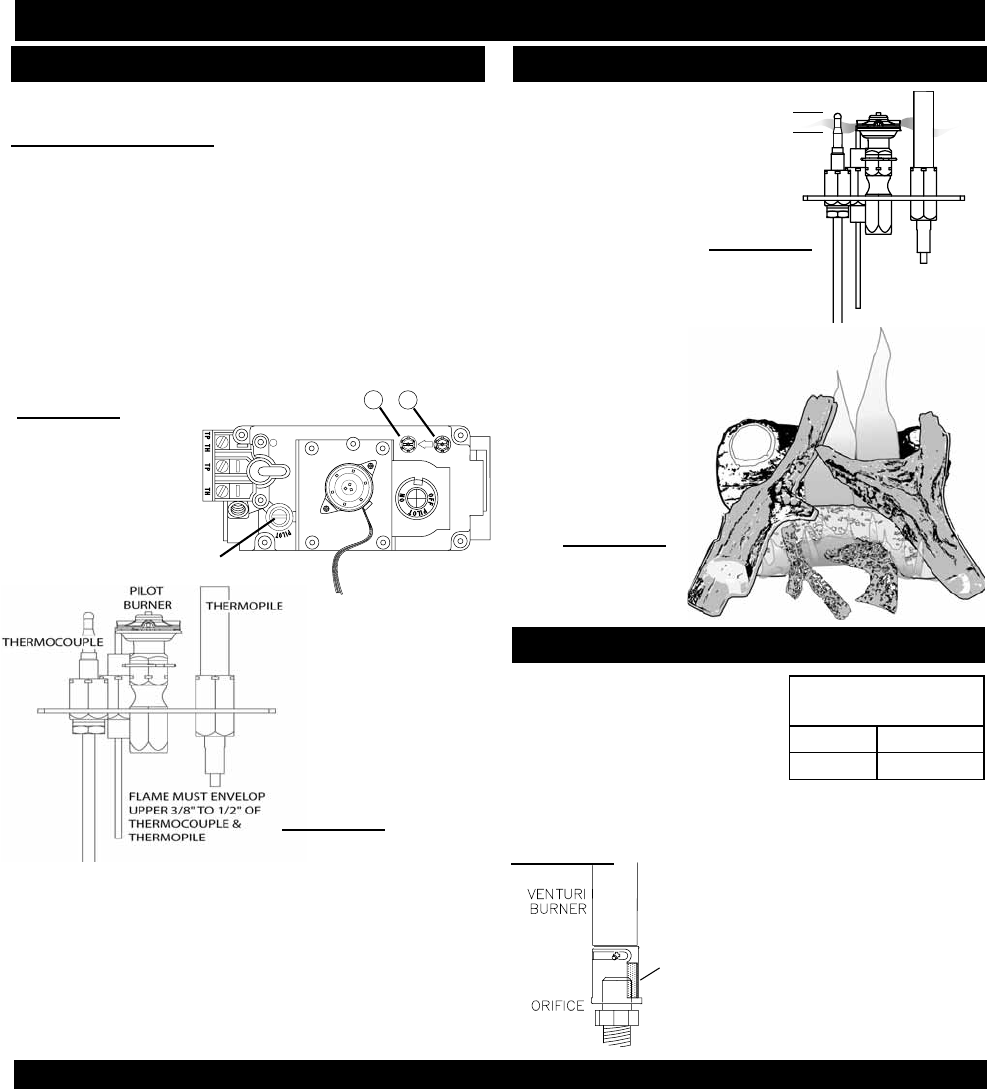

FIGURE 76

Adjust the pilot screw to provide properly sized fl ame. Turn in a

clockwise direction to reduce the gas fl ow.

FIGURE 77

PILOT BURNER ADJUSTMENT

TURN OFF THE GAS AND ELECTRICAL POWER BEFORE

SERVICING THE FIREPLACE.

CAUTION: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing. This fi replace and its venting

system should be inspected before use and at least annually by a

qualifi ed service person. The fi replace area must be kept clear and

free of combustible materials, gasoline or other fl ammable vapors

and liquids. The fl ow of combustion and ventilation air must not be

obstructed.

1. In order to properly clean the burner and pilot assembly, remove

the log and burner to expose both assemblies.

2. Keep the control compartment, log, burner, air shutter opening and

the area surrounding the logs clean by vacuuming or brushing,

at least once a year.

3. Check to see that all burner ports are burning. Clean out any of the

ports which may not be burning or are not burning properly.

4. Check to see that the pilot fl ame is large enough to engulf the

thermocouple and thermopile and reaches toward the burner

with the third jet.

5. Replace the cleaned log and burner.

6. Check to see that the main burner ignites completely on all open-

ings when the gas knob for the burner is turned on. A 5 to 10 second

total light-up period is satisfactory. If ignition takes longer, consult

your Napoleon

®

dealer / distributor.

7. Check that the gasketing on the sides, top and bottom of the door

is not broken or missing. Replace if necessary.

8. If for any reason the vent air intake system is disassembled,

reinstall and re-seal per the instructions provided for the initial

installation.

3/8” - 1/2”

It is important to peri-

odically perform a visual

check of the pilot and

burner fl ames. Compare

them to the illustration

below.

FLAME CHARACTERISTICS

Check Pressure Readings: (Fig. 76)

Inlet pressure can be checked by turning screw (A) counter-clock-

wise 2 or 3 turns and then placing pressure gauge tubing over the

test point. Gauge should read 7” (minimum 4.5”) water column for

natural gas or 13” (11” minimum) water column for propane. Check

that main burner is operating on “HI”.

Outlet pressure can be checked the same as above using screw (B).

Gauge should read 3.5” water column for natural gas or 10” water

column for propane. Check that main burner is operating on “HI”.

AFTER TAKING PRESSURE READINGS, BE SURE TO TURN

SCREWS CLOCKWISE FIRMLY TO RESEAL. DO NOT OVER-

TORQUE.

Leak test with a soap and water solution.

PILOT

SCREW

A

B

FIGURE 78

Closing the air shutter will cause a more

yellow fl ame, but can lead to carboning.

Opening the air shutter will cause a

more blue fl ame, but can cause fl ame

lifting from the burner ports. The fl ame

may not appear yellow immediately; al-

low 15 to 30 minutes for the fi nal fl ame

color to be established.

AIR

SHUTTER

OPENING

FIGURE 80

VENTURI ADJUSTMENT

AIR SHUTTER

OPENINGS

LP 1/2”

NG 1/16”

FIGURE 79

ADJUSTMENTS

MAINTENANCE