Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

8

TROUBLESHOOTING

MAINTENANCE INSTRUCTIONS

Problem Possible Causes Solution

Low heat / Low flame when

valve turned to high.

For propane - improper lighting

procedure.

Ensure lighting procedure is followed carefully. All gas grill

valves mustbe in theoff position whenthe tankvalve is turned

on. Turn tank on slowly to allow pressure to equalize. See

lighting instructions.

For natural gas - undersized sup-

ply line.

Pipe must be sized according to installation code.

For both gases - improper pre-

heating.

Pre-heat grill with both main burners on high for 10 to 15

minutes.

Screw

BURNER - The burner is made from heavy wall 304 stainless steel, but due to the extreme

heat and corrosive environment, surface corrosion will occur. Use a brass wire brush to

remove surface corrosion. Clean any blocked ports using an opened paper clip. Do not

enlarge the burner ports. Spiders and insects are attracted to the smell of propane and

natural gas. The burner is equipped with an insect screen on the air shutter, which will

reduce the likelihood of insects building nests inside the burner, but does not entirely

eliminate the problem. The nest or web will cause the burner to burn with a soft yellow or

orange flame or cause a fire (flashback) at the air shutter underneath the control panel. To

clean the inside of the burner, it must be removed from the gas grill. Remove the screw(s)

located either in the center of the burner on 308 models, or above the burner to the left and

right of the centre of the burner on 450 models. Lift back of burner upwards to remove. Use

a flexible venturi tube cleaning brush to clean out the inside of the burner. Shake any loose

debris out of the burner, through the gas inlet. Ensure that the insect screen is clean, tight,

and free of any lint or other debris. Check also that the valve orifices are clean. Do not enlarge the orifices. Re-install the burner.

Check that the valve enters the burner when installing. Replace burner cover and mounting screws to complete installation.

ALUMINUM CASTINGS - Clean castings periodically with warm soapy water. Aluminum will not rust, but due to high temperatures

and weathering, oxidation can occur on aluminum surfaces. This will appear as white spots on the castings. To refinish the

castings, clean them and sand lightly with fine sandpaper. Wipe surface to remove any residue, and paint with high temperature

barbecue paint. Protect surrounding areas from over-spray. Follow curing directions found on the can.

DARK BLUE

LIGHT BLUE

BURNER

BURNER PORT

Turn off the gas at the source and disconnect unit before servicing. Maintenance should only be done when the grill is cool, to

avoid the possibility ofburns. Aleak testmust be performedannually,and whenever anycomponent of thegas trainis replaced.

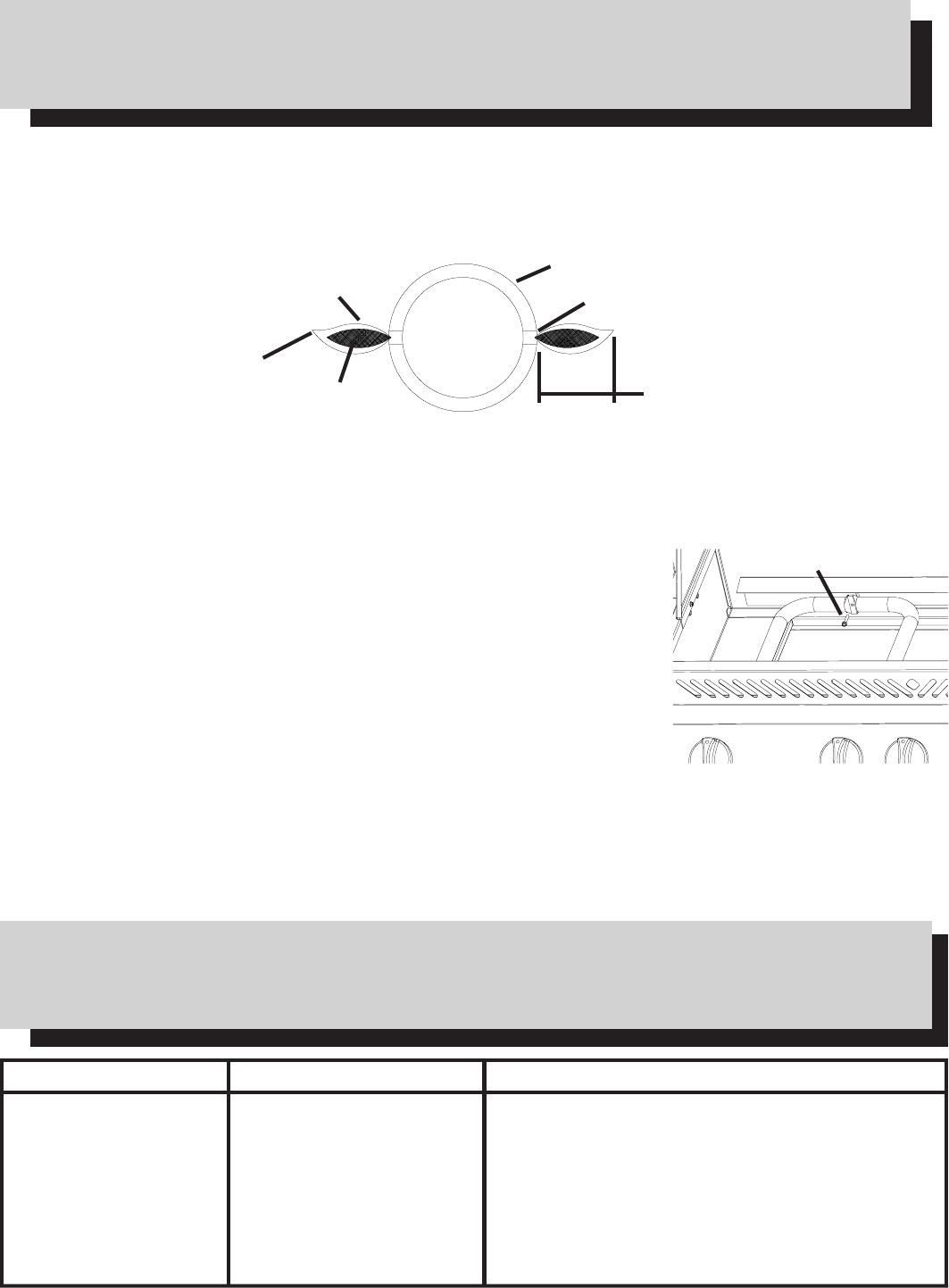

COMBUSTIONAIRADJUSTMENT - (Thismust be doneby a qualifiedgas installer.) The air shutteris factoryset and shouldnot have

to be adjusted under normal conditions. However, some extreme field conditions may exist that require adjustment. When the air

shutter is adjusted correctly, the flames will be dark blue with light blue tips, and occasional yellow tips.

YELLOW TIPPING

If the burner is getting too little air, the flames will be lazy yellow, and possibly produce soot. If the burner is getting too much air, the

flames will be lifting erratically from the burner and may cause difficulties when lighting.

HOSE - Check for abrasion, melting, cuts and cracks. If any of these conditions exist, do not use gas grill. Have part replaced by your

gas grill dealer, or qualified gas installer.

APPROXIMATELY

1/2"