Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

10

English

ASSEMBLY AND OPERATION

APPLICATIONS

⅜

Finishing of dies for press working, die casting and

moulding.

⅜

Finishing of thread cutting dies, tools and other

small parts.

⅜

Internal grinding of tools and machine parts.

WARNING:

To avoid the risk of serious injury, NEVER use this

grinder with abrasive wheels, cut-off wheels and/

or saw blades.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized

conforms to the power source requirements

specified on the product nameplate.

2. Power switch

Ensure that the switch is in the OFF position. If the

plug is connected to a receptacle while the switch

is in the ON position, the power tool will start

operating immediately and can cause serious injury.

3. Extension cord

When the work area is far away from the power

source, use an extension cord of sufficient thick-

ness and rated capacity. The extension cord should

be kept as short as practicable.

WARNING:

Damaged cord must be replaced or

repaired.

4. Check the receptacle

If the receptacle only loosely accepts the plug, the

receptacle must be repaired. Contact a licensed

electrician to make appropriate repairs.

If such a faulty receptacle is used, it may cause

overheating, resulting in a serious hazard.

5. Check the work site and surrounding area

Be sure that the work area has been thoroughly

checked and prepared to avoid any unsafe

conditions. Review the SAFETY section of this

manual.

6. Installing a wheel

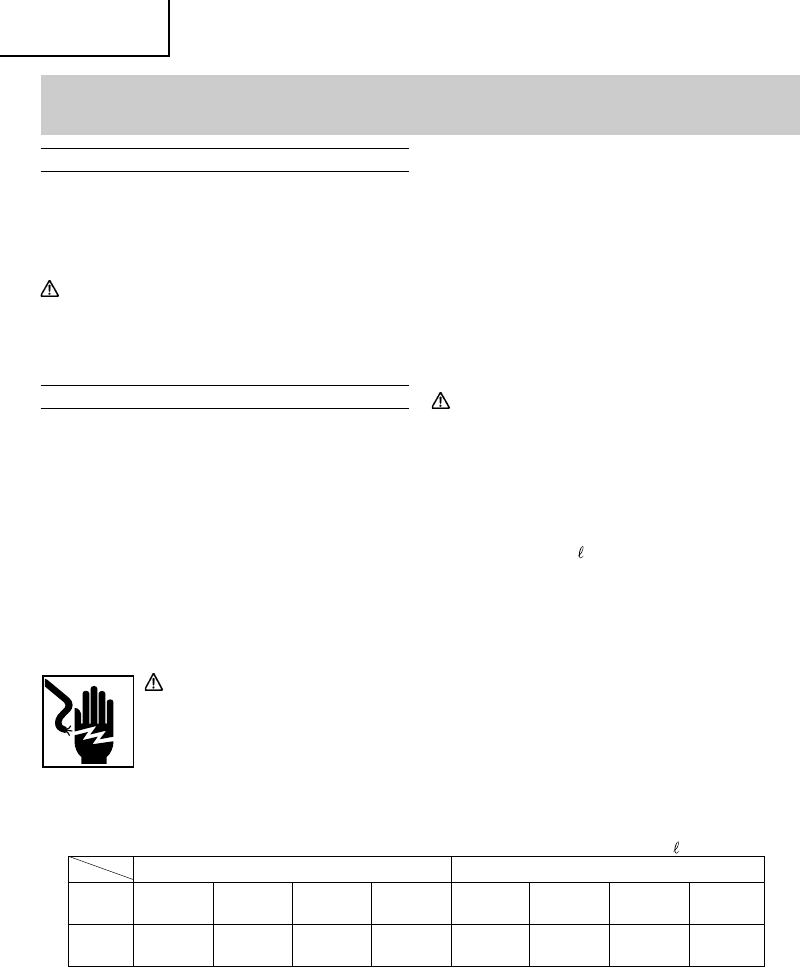

WARNING:

USING A WRONG SIZED WHEEL CAN CAUSE

WHEEL BREAKAGE AND RESULTING SERIOUS

INJURY.

In order to avoid this hazard, refer to the following

illustration to determine the proper dimensions(s)

of your wheel. Some guidelines:

(a) Dimension should always be less than 1/2"

(13 mm). Longer lengths can result in excess

vibration, wheel breakage, and the chance for

serious injury.

(b) When dimension d is 1/4" (6.35 mm), the

diameter of the wheel (dimension D) should

be less than 1" (25 mm). NEVER use a larger

diameter wheel.

(c) When dimension d is 1/8" (3.175 mm), the

diameter of the wheel (dimension D) should

be less than 3/8" (10 mm).

(d) Dimension L varies according to the

dimension D. Dimension L can be longer as

dimension D increase. Refer to the following

table:

(When =1/2’’(13mm))

d

1/8’’(3.175mm) 1/4’’(6.35mm)

D

3/16’’ 1/4’’ 5/16’’ 3/8’’ 1/2’’ 5/8’’ 3/4’’ 1’’

(5mm) (6mm) (8mm) (10mm) (13mm) (16mm) (20mm) (25mm)

L

1/2’’ 3/4’’ 3/4’’ 3/4’’ 1-1/2’’ 1’’ 1’’ 3/4’’

(13mm) (20mm) (20mm) (20mm) (38mm) (25mm) (25mm) (20mm)

01Eng_GP2S2_US 4/5/11, 10:25 AM10