Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

16

W415-0244 / A / 05.15.03

Proceed once the vent installation is complete.

1. Move the fireplace into position and secure using the

nailing tabs and/or secure to the floor through the ¼"diam-

eter holes located at either end of the base.

2. Route a 3/8" N.P.T. black iron gas line, 1/2" type-L cop-

per tubing or equivalent to the fireplace.

3. For ease of accessibility, an optional remote wall switch

or millivolt thermostat may be installed in a convenient lo-

cation. Route 2-strand (solid core) millivolt wire through

the electrical hole located at the bottom left side of the unit.

The recommended maximum lead length depends on wire

size:

WIRE SIZE MAX. LENGTH

14 gauge 100 feet

16 gauge 60 feet

18 gauge 40 feet

Attach the two leads to terminals 1 and 3 located on the

gas valve.

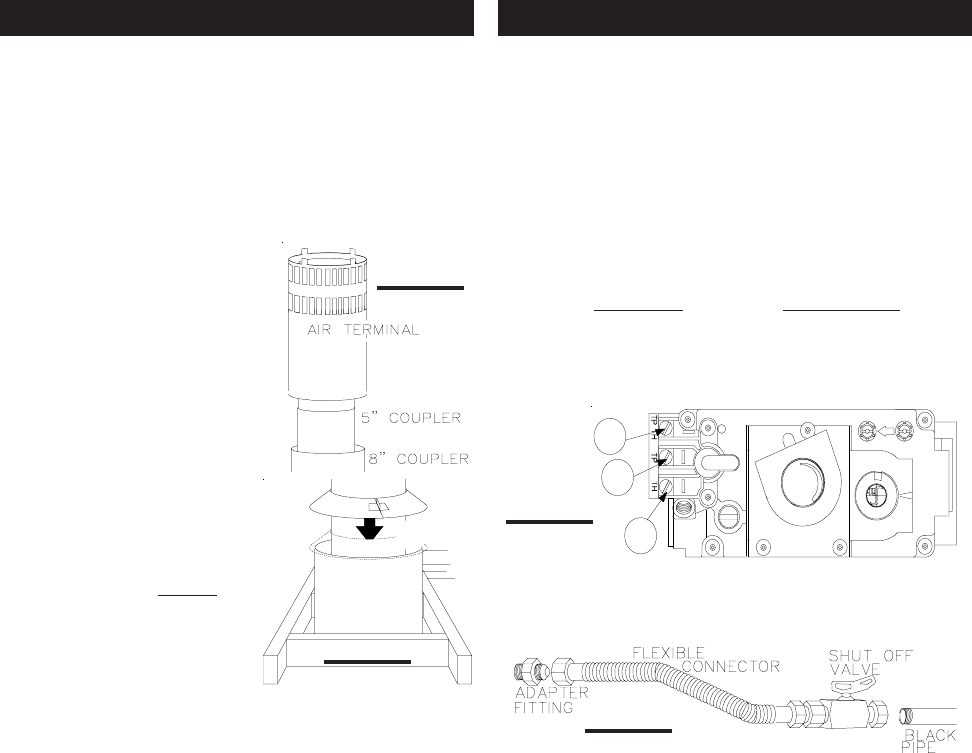

4. Install rigid black pipe, 1/2" type-L copper tubing or, if

local codes permit, a 3/8" flex connector and shutoff valve

to the gas line and the fireplace gas valve.

The gas line and the shutoff valve (if so equipped) must

not interfere with the opening and closing of the door

latch.

Seal and tighten securely. An adapter fitting is required

between the gas valve and the copper tubing or flex con-

nector.

DD

DD

Do not kink flex connector.

5. Check for gas leaks by brushing on a soap and water

solution.

Do not use open flame.

Do not connect either the wall switch, thermostat or gas

valve to electricity (110 volts).

Purge all gas lines with the glass door of the fireplace

open. Assure that a continuous gas flow is at the burner

before closing the door.

1. Move the fireplace into position.

2. Fasten the roof support to the roof using the screws

provided. FIGURE 22. The roof support is optional. In this

case the venting is to be adequately supported using ei-

ther an alternate method suitable to the authority having

jurisdiction or the optional roof support.

3. Apply high temperature sealant to the outer edge of the

inner sleeve of the air terminal. Slip a 5" diameter coupler a

minimum of 2" over the sleeve and secure using 3 screws.

4. Apply high temperature seal-

ant to the outer edge of the of the

outside sleeve of the air terminal.

Slip a 8" diameter coupler over the

sleeve and secure as before. FIG-

URE 27. Trim the 8" coupler even

with the 5" coupler end.

5. Thread the air terminal pipe

assembly down through the roof

support and attach, ensuring that

a minimum 16" of air terminal will

penetrate the roof when fas-

tened. FIGURE 22. If the attic

space is tight, we recommend

threading the Wolf Steel vent pipe

collar or equivalent loosely onto

the air terminal assembly as it is

passed through the attic.

FIGURE 28. The air terminal must

be located vertically and plumb.

6. Remove nails from the shingles, above and to the

sides of the chimney. Place the flashing over the air termi-

nal and slide it underneath the sides and upper edge of

the shingles. Ensure that the air terminal is properly

centered within the flashing, giving a 3/4" margin all around.

Fasten to the roof. Do NOT nail through the lower portion of

the flashing. Make weather-tight by sealing with caulking.

Where possible, cover the sides and top edges of the flash-

ing with roofing material. FIGURE 23.

7. Apply a heavy bead of waterproof caulking 2 inches

above the flashing. Slide the storm collar around the air

terminal and down to the caulking. Tighten to ensure that a

weather-tight seal between the air terminal and the collar

is achieved. Attach the other storm collar centered between

the air intake and air exhaust slots onto the air terminal.

Tighten securely. Attach the rain cap.

8. Continue adding rigid venting sections, sealing and

securing as above. Attach a 5" collapsed telescopic pipe

to the last section of rigid piping. Secure with screws and

seal. Repeat using a 8" telescopic pipe.

9. Run a bead of high temperature sealant around the

outside of the 5" collar on the fireplace. Pull the adjustable

pipe a minimum of 2" onto the collar. Secure with 3 screws.

Repeat with the 8" telescopic pipe.

10. In the attic, slide the vent pipe collar down to cover up

the open end of the shield and tighten. This will prevent

any materials, such as insulation, from filling up the 1" air

space around the pipe.

VENT PIPE

SHIELD

VEN

T

PIP

E

COLLA

R

FIGURE 28

FIGURE 27

FIGURE 30

FIGURE 29

P

I

P

I

L

O

T

3

1

2

N

O

L

O

T

H

I

L

O

F

F

O

VERTICAL VENTING INSTALLATION GAS INSTALLATION