Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

11

104277

OWNER’S MANUAL

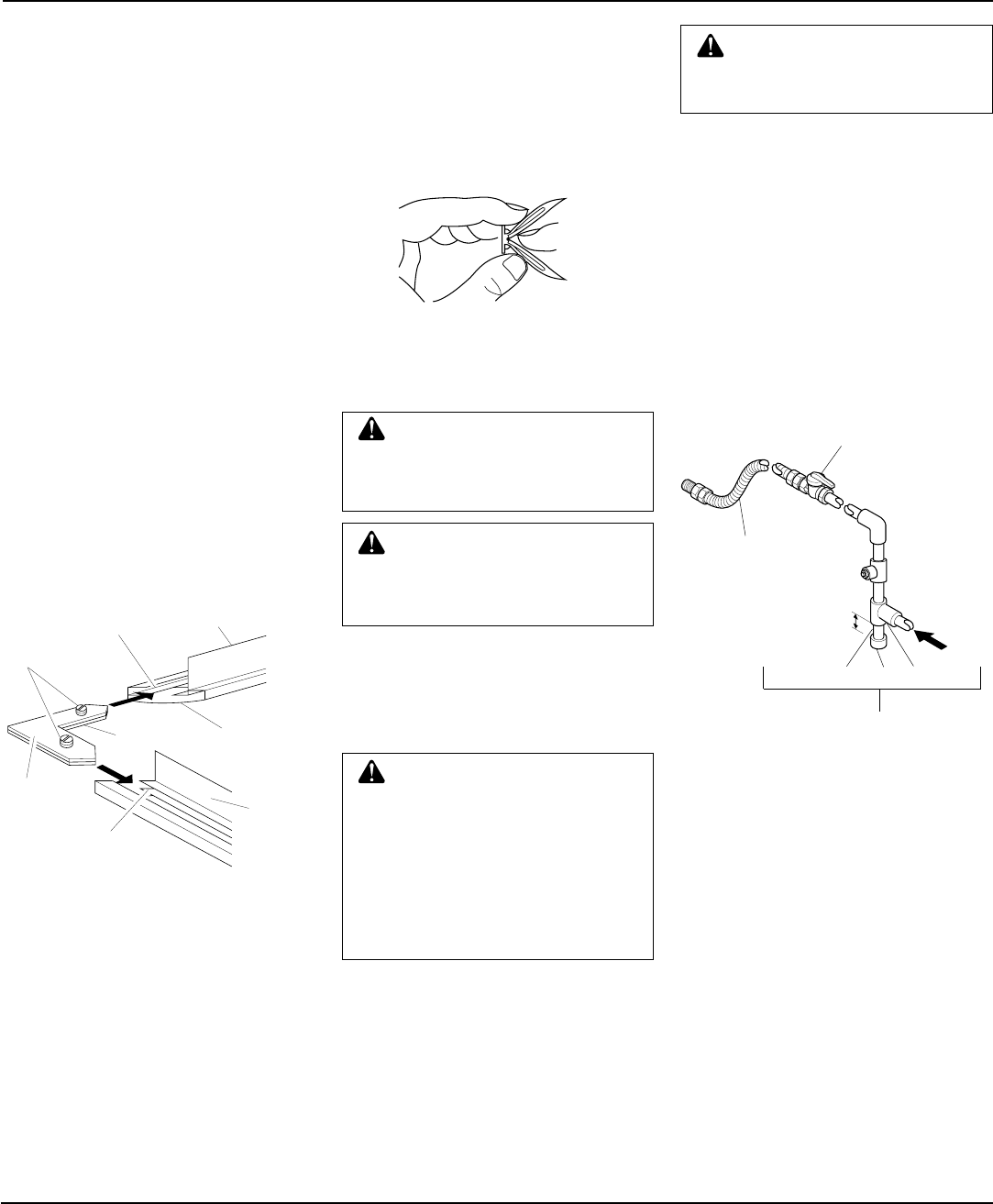

CONNECTING TO GAS

SUPPLY

WARNING: A qualified ser-

vice person must connect fire-

place to gas supply. Follow all

local codes.

IMPORTANT:

Check gas line pressure

before connecting fireplace to gas line. Gas

line pressure must be no greater than 14

inches of water. If gas line pressure is higher,

fireplace regulator damage could occur.

Installation must include a manual shutoff

valve, union, and plugged 1/8" NPT tap.

Locate NPT tap within reach for test gauge

hook up. NPT tap must be upstream from

fireplace (see Figure 16).

Apply pipe joint sealant lightly to male

threads. This will prevent excess sealant

from going into pipe. Excess sealant in pipe

could result in clogged fireplace valves.

Install sediment trap in supply line as

shown in Figure 16. Locate sediment

trap where it is within reach for

cleaning. Locate sediment trap where

trapped matter is not likely to freeze.

A sediment trap traps moisture and

contaminants. This keeps them from

going into fireplace controls. If

sediment trap is not installed or is

installed wrong, fireplace may not run

properly.

WARNING: Never connect

fireplace to private (non-utility)

gas wells. This gas is commonly

known as wellhead gas.

CAUTION: Use only new,

black iron or steel pipe. Inter-

nally-tinned copper tubing may

be used in certain areas. Check

your local codes. Use pipe of 1/2"

or greater diameter to allow

proper gas volume to fireplace. If

pipe is too small, undue loss of

pressure will occur.

CAUTION: Use pipe joint seal-

ant that is resistant to liquid pe-

troleum (LP) gas.

* Purchase the optional A.G.A. design-cer-

tified manual shutoff valve from your dealer.

See Accessories, page 22.

Figure 16 - Gas Connection

ATTACHING WOOD BASE TO

SOLID FLOOR

For attaching base to solid floors (concrete

or masonry)

Note:

Floor anchors and mounting screws

are in hardware package. The hardware pack-

age is provided with fireplace.

1. Drill holes at marked locations using

5/16" drill bit. For solid floors (concrete

or masonry), drill at least 1" deep.

Figure 15 - Folding Anchor

ASSEMBLING BRASS TRIM

(Brass trim shipped with

mantel)

1. Remove packaging from three remain-

ing pieces of brass trim.

2. Locate two adjusting plates with set

screws, and two shims in the hardware

packet.

3. Align shim under adjusting plate as

shown in Figure 14.

4. Slide one end of adjusting plate/shim

in slot on mitered edge of top brass trim

(see Figure 14).

5. Slide other end of adjusting plate/shim

in slot on mitered edge of side brass

trim (see Figure 14).

6. While firmly holding edges of brass

trim together, tighten both set screws

on the adjusting plate with slotted

screwdriver.

7.

Repeat steps 1 through 6 for other corner.

8. Set brass a7ssembly aside for later

installation.

Figure 14 - Assembling Brass Trim

INSTALLATION

Continued

Top Brass Trim

Side

Brass

Trim

Mitered

Edge

Shim

Set

Screws

Adjusting

Plate

Slot

Slot

A.G.A. Design-Certified

Manual Shutoff Valve

With 1/8" NPT Tap*

3" Minimum

From Gas

Meter

(5" W.C. to

10.5" W.C.

Pressure)

Approved

Flexible Gas Line

Pipe Nipple Cap Tee Joint

Sediment Trap

2. Fold floor anchor as shown in Figure 15.

3. Insert floor anchor (wings first) into

hole. Tap anchor flush to floor.

4. Insert mounting screws through base

and into floor anchors.

5. Tighten screws until base is firmly fas-

tened to floor.

Continued