Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

28

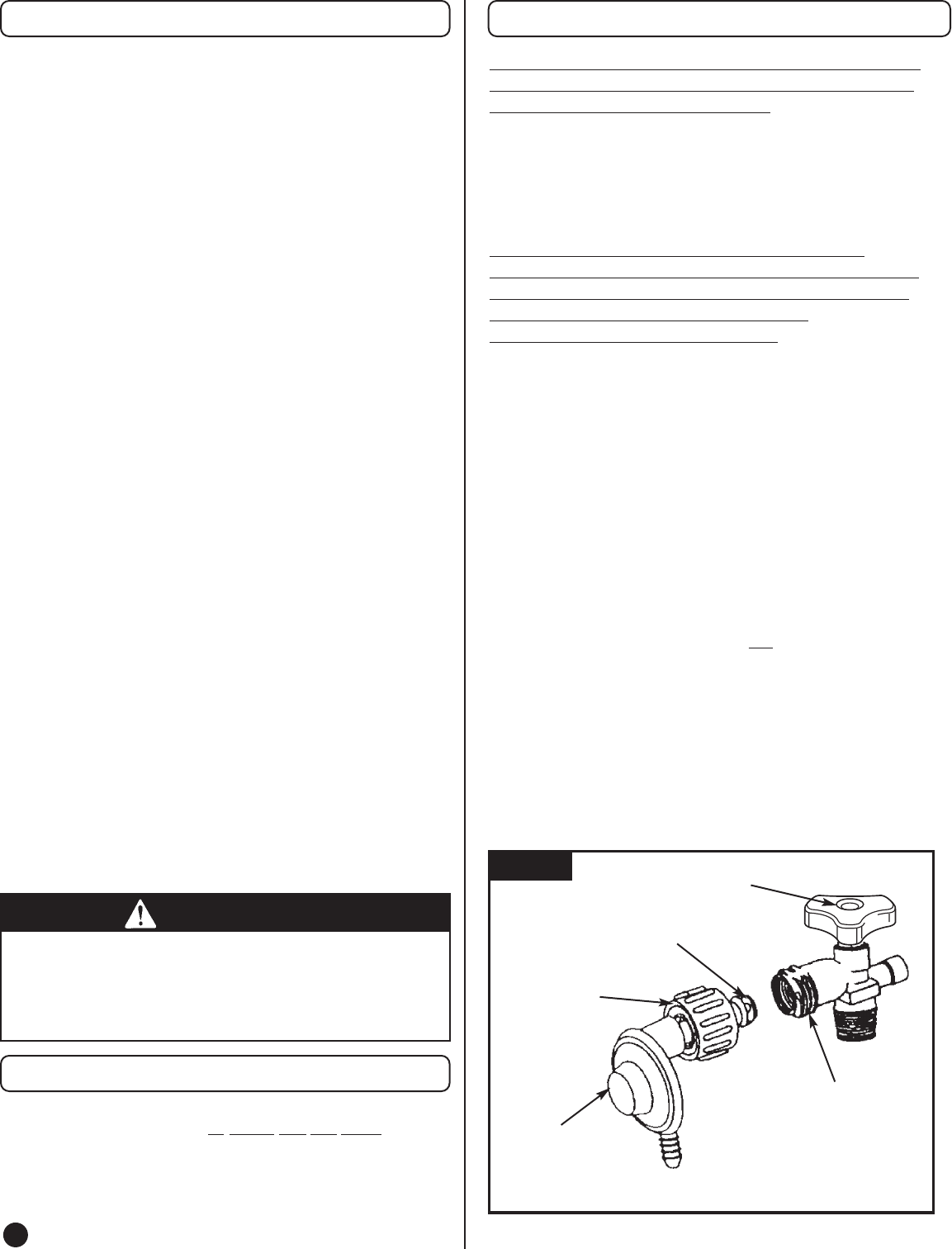

TYPE 1 CONNECTION ILLUSTRATION

Thermal

Sensitive

Handwheel

1-5/16"

Acme Connection

Nipple with

Excess Flow

Valve

Regulator

YOUR NEW GAS GRILL IS EQUIPPED WITH A

TYPE 1 CONNECTION DEVICE WHICH HAS 3

SAFETY FEATURES (FIG. 64):

1. Proof of gas seal between the connector and the cylinder

before gas flow takes place.

2. A flow-limiting device designed to limit the flow of gas in

the event of a regulator or hose failure.

3. The connection has a thermal shut-off which will stop the

flow of gas if the connection reaches a certain temperature.

CURRENT GAS CYLINDERS ARE ALSO

EQUIPPED WITH AN OVERFILL PR

OTECTION

DEVICE (O.P.D.)

WHICH GREATLY REDUCES

THE CHANCE OF ACCIDENTALLY

OVERFILLING THE CYLINDER.

SPECIAL NOTE CONCERNING L.P. GAS CYLINDERS:

It is important to insure that your gas cylinder is properly

purged before it is filled. If you purchase a new cylinder,

please inform your propane gas dealer that this is a new

cylinder and needs to be properly purged before being filled.

SPECIAL NOTE CONCERNING TYPE 1 CONNECTION

DEVICES:

If you notice very small flames on the burner(s), you may have

accidentally activated the flow-limiting device in the Type 1

connection device. Besides a rupture in the gas hose, the

flow-limiting device may activate for one of the two following

reasons:

1. Opening the burner valves before opening the cylinder

valve. SOLUTION: Shut off the burner valves and the L.P.

cylinder valve and open in the proper order:

a). Open the L.P. cylinder valve first

, then

b). Open burner valve and ignite the burner

according to the instructions in this manual for

your grill.

IF YOU STILL HAVE A PROBLEM, THEN THERE MAY BE AIR IN

THE CYLINDER DUE TO IMPROPER PURGING.

2. The L.P. cylinder was not properly purged before it was filled.

SOLUTION: See your L.P. gas supplier.

For Your Additional Safety

DANGER

If a fire occurs at the cylinder valve, DO NOT attempt to move

the cylinder. IMMEDIATELY call the fire department and clear

the area. You can safely spray water with a garden hose from

a distance of at least 15 feet away from cylinder until firemen

arrive.

Troubleshooting

(continued)

For Your Additional Safety

(continued)

Current L.P. gas cylinders are fitted with an Overfill

Protection Device (O.P.D.). T

o insure that you retain this

safety-device, take your cylinder to an L.P. gas service

station for filling, or when exchanging your cylinder at a

cylinder exchange station, request that your replacement

cylinder be fitted with the O.P.D. feature.

Problem: Flame blows out on low setting or

has uneven heat distribution.

Possible Causes and Solutions:

1. Check for spider webs or insect nests in the venturi and clean

the venturi.

2. Cold grill needs to be preheated for 5 minutes on high

setting.

3. The venturi may be misaligned and needs to be lined up

over the orifices.

4. Cold and windy weather will require you to move the grill

away from the wind.

5. Lack of fuel. Check to see that the cylinder valve is open and

that the cylinder has fuel.

Problem: Grill too hot.

Possible Causes and Solutions:

1. Excessive flareups which require the maintenance described

in the section titled “IN CASE OF GREASE FIRE”.

2. A damaged orifice or regulator which requires replacement

with factory authorized parts.

3. Buildup of grease inside the grill will require cleaning and

emptying the grease tray.

4. Choose a lower cooking temperature if using excessively

high settings.

Problem: Fire at any connection.

Possible Causes and Solutions:

IMMEDIATELY shut off cylinder valve and allow grill to cool.

1. Gas is leaking from a faulty connection. Tighten connections

with an adjustable wrench and replace damaged parts.

Perform a leak test on all connections before cooking on the

grill again.

Problem: Flame behind control panel or

control knob area.

Possible Causes and Solutions:

IMMEDIATELY shut off cylinder valve and allow grill to cool.

1. Check for spider webs or insect nest in the venturi and clean

the venturi.

2. Gas is leaking from a faulty connection. Tighten connections

with an adjustable wrench and replace damaged parts.

Perform a leak test on all connections before cooking on the

grill again.

3. The venturi may be misaligned and needs to be lined up over

the orifices.

Fig. 64