Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

Buy Weber Grill Parts. It couldn't be easier. Find your Weber parts here.

13

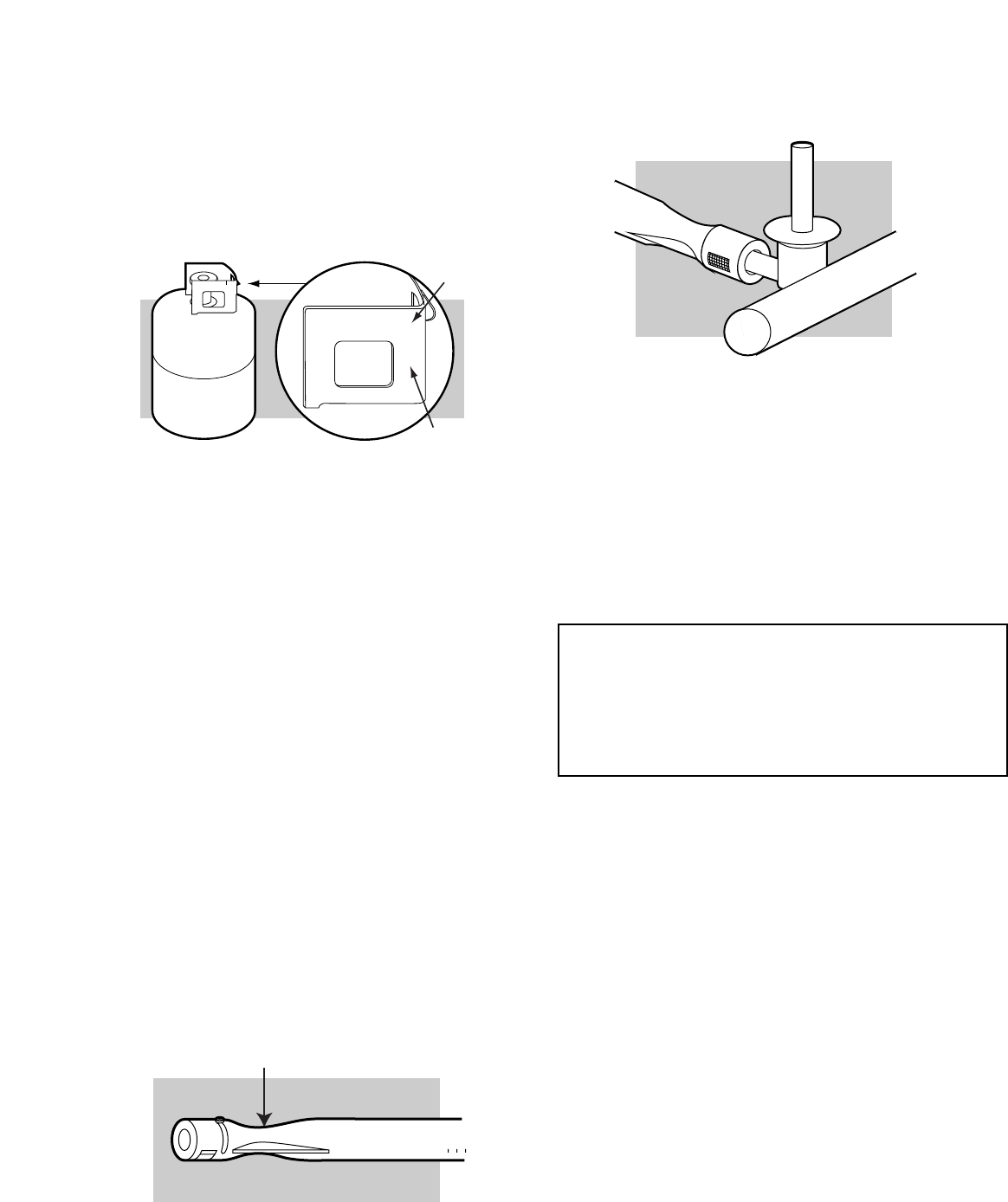

Spider/Insect screens

Your Gas Barbecue, as well as any outdoor gas

appliance, is a target for spiders and other insects.

They can nest in the venturi section Venturi(1) of the

burner tubes. This blocks the normal gas flow, and can

cause the gas to flow back out of the air shutter. Figure 5.

This could result in a fire in and around the air shutters,

under the control panel, causing serious damage to

your barbecue.

(1)

We recommend that you inspect the Spider/Insect

screens at least once a year. Also inspect and clean

the Spider/Insect screens if any of the following

symptoms should ever occur.

1. The smell of gas in conjunction with the burner flames

appearing yellow and lazy.

2. Barbecue does not reach temperature.

3. Barbecue heats unevenly.

4. One or more of the burners do not ignite.

ƽ DANGER

Failure to correct these symptoms may

result in a fire which can cause serious

bodily injury or death and cause damage

to property.

GENERAL MAINTENANCE

Inspection and cleaning of the

Spider/Insect screens

To inspect the spider/insect screens, remove the control

panel. If there is dust or dirt on the screens, remove the

burners for cleaning the screens. Refer to Maintenance,

Replacing Main Burners. Brush the spider/inspect

screens, lightly, with a soft bristle brush (i.e. an old

toothbrush).

ƽ Caution:

Do not clean the spider/insect screens

with hard or sharp tools. Do not dislodge

the spider/insect screens or enlarge the

screen openings.

Lightly tap the burner to get debris and dirt out of the

burner tube. Once the spider/insect screens and burners

are clean replace the burners.

If the spider/insect screen becomes damaged or cannot

be cleaned, call Weber-Stephen Products Customer

Service for replacement parts.

The burner tube air shutter is fitted with a stainless steel

screen(1) to prevent spiders and other insects access to

the burner tubes through the air shutter openings.

Liquid Propane Cylinder requirements

• Replacement LP cylinders supplied by Weber satisfy the

above requirements. Check to be sure other cylinders

have a D.O.T. certification(1), and date tested(2) is within

five years.Your LP gas supplier can do this for you.

If you have questions about spare LP cylinders

contact the Customer Service Representative in your

region using the contact information sheet provided

with your manual.

DOT 4BA240

00/01

(1)

(2)

• All LP tank supply systems must include a collar to

protect the cylinder valve.

• The LP cylinder must be a 20-lb. size (18

1

⁄4 inches high,

12

1

⁄4 inches in diameter).

• The LP cylinder must be constructed and marked in

accordance with the specifications for LP gas cylinders

of the U.S. Department of Transportation (D.O.T.).