Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

WWW.WEbEr.com

®

23

GaS SUPPLY

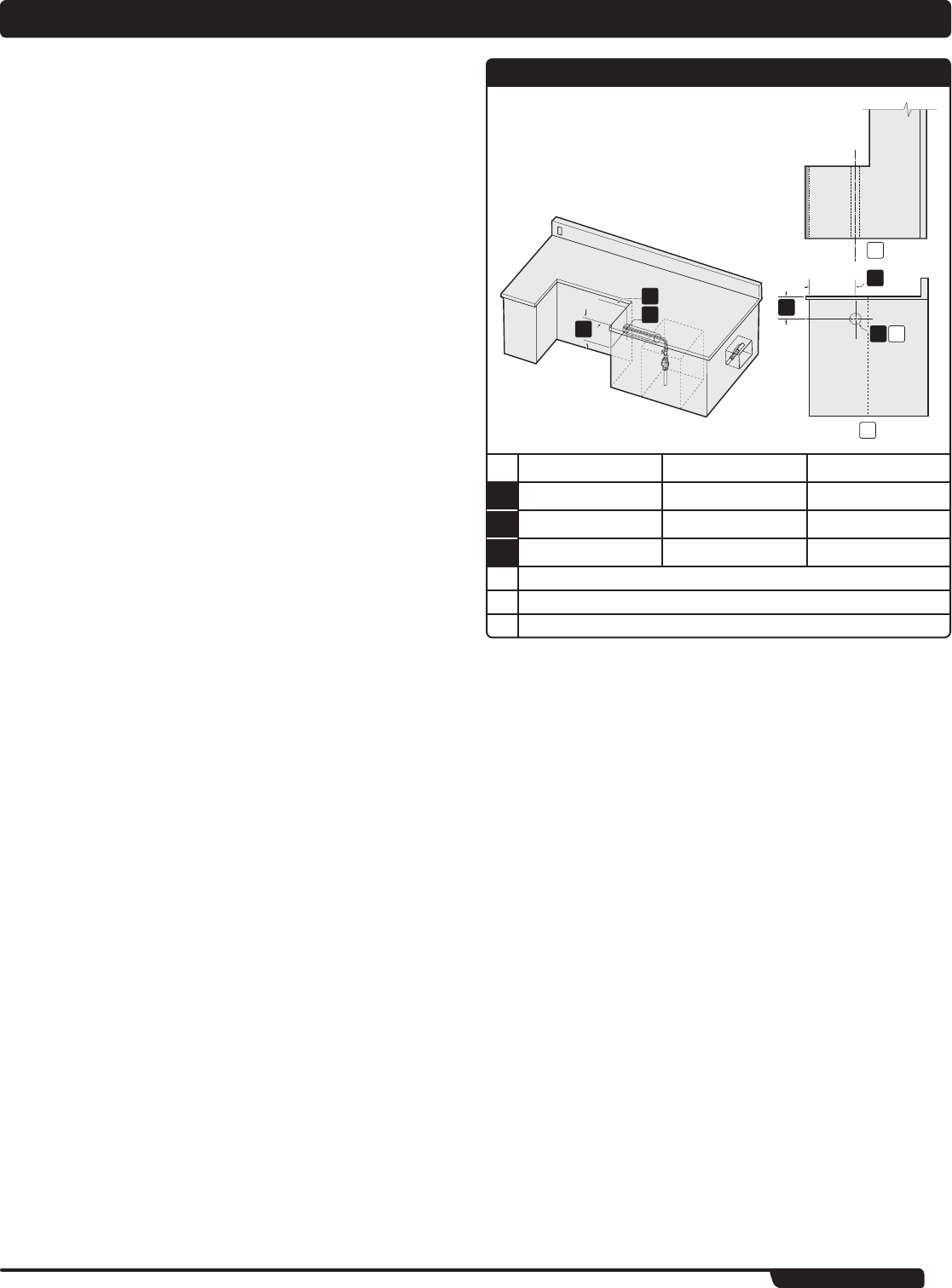

bUILT-IN GaS LINE LocaTIoNS

3

1

2

c

a

b

1

2

3

460 660 ToLEraNcES

1 16 1/2" (419.1 mm) 16 1/2" (419.1 mm) ±1/8" (3.2 mm)

2 11 1/8" (282.6 mm) 11 1/8" (282.6 mm) ±1/8" (3.2 mm)

3 2 1/2" (63.5 mm) 2 1/2" (63.5 mm) ±1/8" (3.2 mm)

a Plan view right

b Side view

c Gas inlet

BUILT-IN GAS LINE LOCATIONS

Note: Leave an access in the “island” structure for gas supply and regulator service that

is not inside the grill structure.

Note: Area should be kept clear of sharp, jagged, or extremely abrasive surfaces to

avoid possible damage to gas supply lines. Exercise caution when pulling gas lines

through built-in structure.

◆

TYPICAL NATURAL GAS SUPPLY INSTALLATION

We recommend that this installation be done by a LICENSED professional.

General Specifications For Piping

Note - Contact your local municipality for building codes regulating outdoor gas grill

installations. In absence of Local Codes, you must conform to the latest edition of

National Fuel Gas Code ANSI Z223.1/NFPA54.

• Thisgrillisdesignedtooperateat4.5inchesofwatercolumnpressure.

• Amanualshut-offvalvemustbeinstalledoutdoors,andbeaccessible,notinthe

“built-in” structure. An additional manual shut-off valve indoors should be installed in

the branch fuel line in an accessible location near the supply line.

m CAUTION: If young children are in the area, a locking valve

should be considered.

• Pipecompoundshouldbeusedwhichisresistanttotheactionofliquidpropanegas

when gas connections are made.

• Thegasconnectionsmustbefirmlyattachedtoarigid,permanentconstruction.

Note: The information provided in this manual is general for typical installations. We

cannot cover all possible installation ideas. We recommend, prior to installation, that you

contact your municipality for local building codes and your local fire department for

installation verification.

If you have any questions, contact Customer Service at 1-800-446-1071.

◆

GAS LINE PIPING

• Refertopipingchart.

• Thecorrugatedgaslinefromthemanifoldis58"(1,473.2mm)long.Donotextend

the gas line.

• WehaveprovidedthemeanstomakeanSAE45°flareconnection.Donotusepipe

sealant on this connection.

• Ifthelengthoflinerequireddoesnotexceed50feet,usea5/8"O.D.tube.Onesize

larger should be used for lengths greater than 50 feet. Refer to piping chart.

• Gaspipingmaybecoppertubing,typeKorL;polyethyleneplastictube,witha

minimumwallthicknessof.062"(1.57mm);orstandardweight(schedule40)steelor

wrought iron pipe.

• Coppertubingmustbetin-linedifthegascontainsmorethan0.3gramsofhydrogen

sulfide per 100 cubic feet of gas.

• Plastictubingissuitableonlyforoutdoor,undergrounduse.

• Gaspipingincontactwithearth,oranyothermaterialwhichmaycorrodethepiping,

must be protected against corrosion in an approved manner.

• Undergroundpipingmusthaveaminimumof18"cover.

◆