Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

Be sure that the fuel source designated on your

grill head is the same as that of the support

system.

DO NOT USE A GRILL HEAD EQUIPPED

FOR NATURAL GAS WITH LP GAS OR

THE OPPOSITE.

Maximum inlet pressure from System LP cannot

exceed 11" W.C. The proper orifices and valving for

each gas is contained in the grill head. Maximum

pressure for Natural Gas is 7" W.C.

3. VERIFY ALL PARTS. IF YOU ARE MISSING ANY

PARTS, PLEASE CONTACT YOUR PGS DEALER.

4. REMOVE PROTECTIVE FILM FROM ALL

STAINLESS STEEL COMPONENTS (Be careful not

to scratch stainless steel parts).

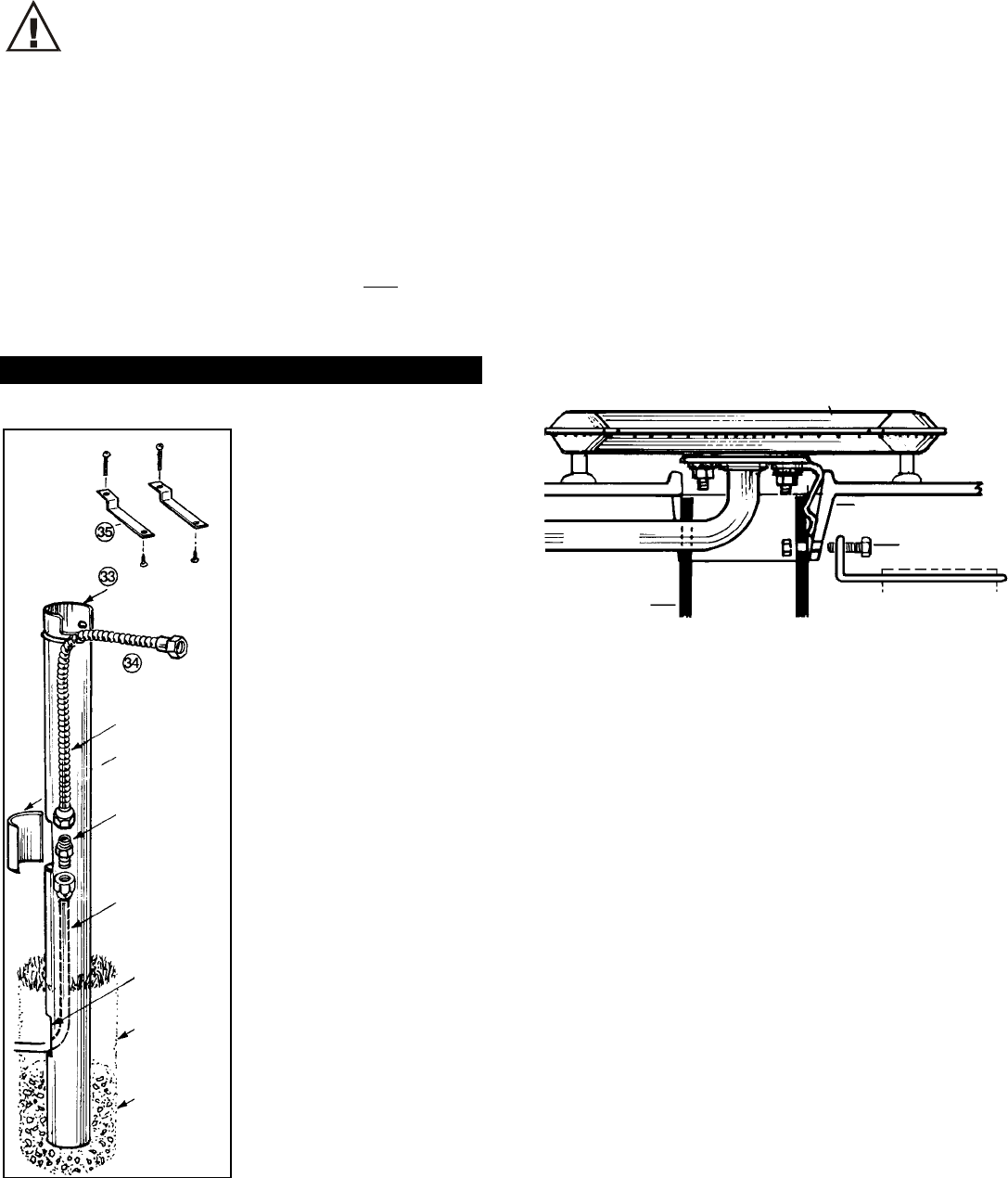

PERMANENT POST (IN GROUND) MOUNTING

Your PGS permanent post

is made of aluminum.

Although aluminum is

extremely resistant to

outdoor conditions,

caution should be taken to

protect against soil

ns in your area.

Please consult your dealer

for further information.

conditio

GRILL

B

POS

INTO

1. A g

surface

damage

You mu

line r

and hav

CONTROL

PANEL

STIFFENING

BRACKETS

IN-GROUND

8”POST

STAINLESS

STEELTUBING

ACCESS

DOOR

3/8” FLARE

COUPLING

(Not Included)

GAS SUPPLY

LINE

ACCESS

HOLE ON

BACK OF

POST

8” DIA. HOLE

24” DEEP

CEMENT

PLEASE NOTE: THE

HEAD IS NOT TO

E FASTENED TO THE

48" POST UNTIL THE

T IS CEMENTED

THE GROUND.

as supply line

should be trenched at

least 18" below the ground

to prevent

from digging.

st have a supply

egulated to 7" W.C.

e a master shut

off valve.

PLEASE CHECK WITH

LOCAL CODES FOR

LOCAL REGULATIONS.

2. Dig a posthole 8" in

diameter and two feet

deep. Locate the hole so

the grill will be at least 30" away from any combustible

object or surface: above, back, left or right. The

access hole is on the BACK of the post and the

notches at the top are on the front of the post. Center

the post in the hole and plumb it with a level. Pour

cement up to the gas line access hole.

3. Run the gas supply line into the post making a 90-

degree bend to reach the access door. Connect steel

connector supplied with post to gas supply line.

4. Remove the grill burner from the lower grill casting

by disengaging the burner from the lower casting.

5. Carefully set grill head in place. Pass three 1/4" X

20" X 3/4" bolts provided in permanent post box

through grill head cast collar and then through holes in

permanent post. Attach three 1/4" X 20" kep nuts.

Then attach the grease cup holder at this time on rear

center bolt. Securely tighten all nuts and bolts (see

illustration below). Insert an empty soup can in grease

cup holder to catch juices.

K-30 BURNER

POST FLANGE

VENTURI

BOLTS

ATT

ACH POST

GREASE CUP

POST HOLDER

Grill head to permanent post assembly

REMOVE PROTECTIVE FILM FROM CONTROL

PANEL, COLLAR BOX AND ROCK GRATES

6. You will note that the bolts already attached to the

control panel have two nuts on each of them. Remove

the plastic thread protectors and discard. Remove the

top nut on each bolt and make certain lower nut is

securely tightened against control panel.

7. Attach gas line from permanent post to valve

assembly. BE CERTAIN NOT TO CROSS THREAD.

Hand-tighten only at this time.

8. Insert 3/4" bolts (Pre-assembled on control panel)

through grill head, attach nuts and securely tighten.

Tighten gas line to valve assembly.

14