Special offers from our partners!

Find Replacement BBQ Parts for 20,308 Models. Repair your BBQ today.

10

W415-0583 / B / 05.23.07

This application occurs

when venting through

a roof. Installation kits

for various roof pitches

are available from your

Napoleon® dealer. See

Accessories to order the

specifi c kit required.

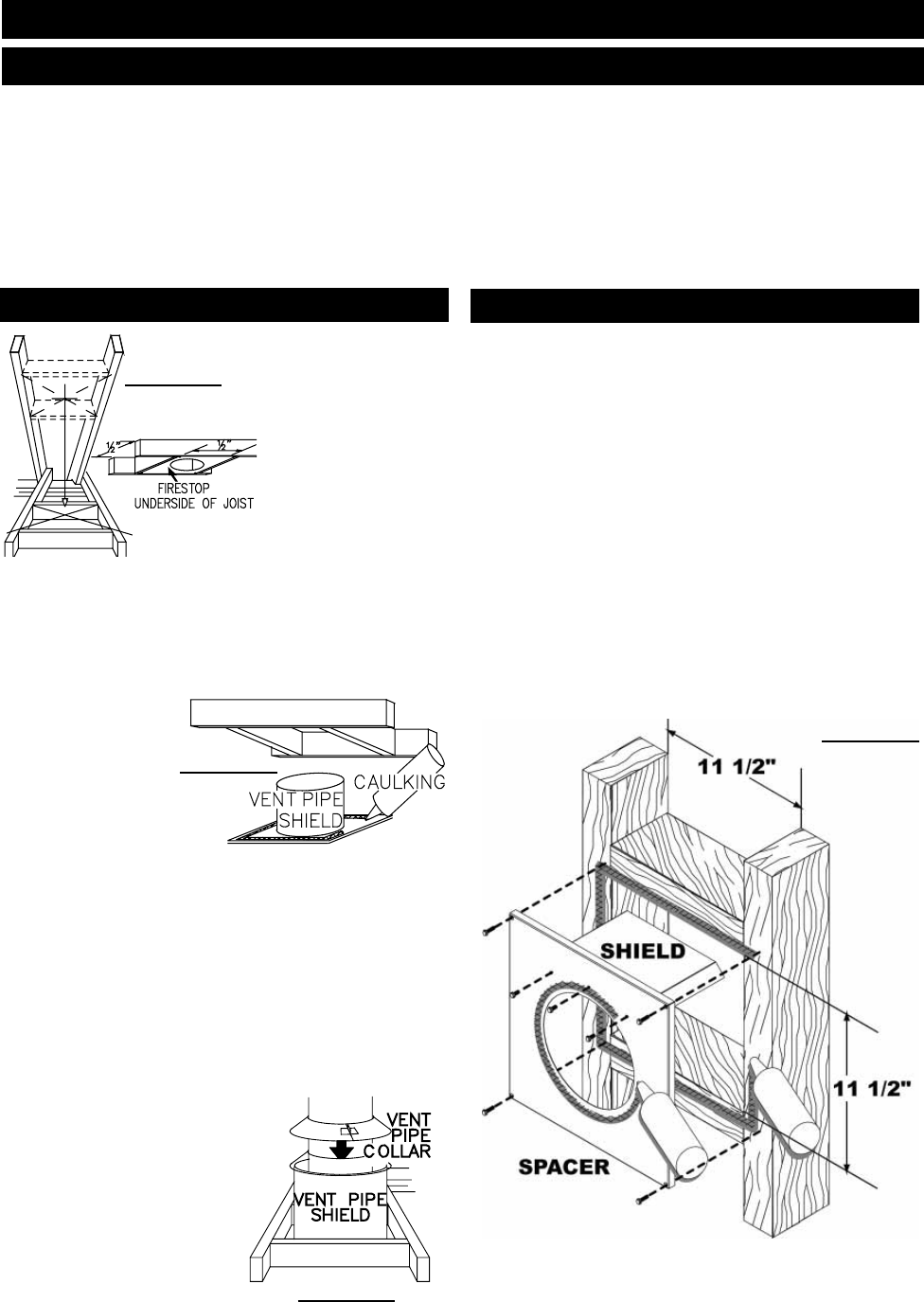

1. Determine the air

terminal location, cut

and frame 11½ inch

openings in the ceiling

and the roof to provide the minimum clearance between the

fi replace pipe / liner and any combustible material. Try to

center the exhaust pipe location midway between two joist

to prevent having to cut them. Use a plumb bob to line up the

center of the openings.

DO NOT FILL THIS SPACE WITH ANY TYPE OF MATERIAL.

A vent pipe shield will

prevent any materi-

als such as insulation,

from fi lling up the 1" air

space around the pipe.

Nail headers between

the joist for extra sup-

port.

2. Apply a bead of

caulking (not supplied) to the framework or to the Wolf Steel

vent pipe shield plate or equivalent (in the case of a fi nished

ceiling), and secure over the opening in the ceiling. A fi restop

must be placed on the bottom of each framed opening in a

roof or ceiling that the venting system passes through. Apply

a bead of caulking all around and place a fi restop spacer

over the vent shield to restrict cold air from being drawn into

the room or around the fi replace. Ensure that both spacer

and shield maintain the required clearance to combustibles.

Once the vent pipe / liner is installed in its fi nal position, apply

sealant between the pipe / liner

and the fi restop spacer.

3. In the attic, after the pipe /

liner has been installed, slide the

vent pipe collar down to cover up

the open end of the shield and

tighten. This will prevent any

materials, such as insulation,

from fi lling up the 1" air space

around the pipe.

INSTALLATION

WALL AND CEILING PROTECTION

VERTICAL INSTALLATION

VENT PIPE

SHIELD

VENT

PIPE

COLLAR

FIGURE 15

FIGURE 14

11

11

FIGURE 13

For optimum performance it is recommended that all horizontal runs have a minimum ¼ inch rise per foot using

fl exible venting.

For safe and proper operation of the fi replace, follow the venting instructions exactly.

HORIZONTAL TERMINATION: A clearance to combustibles of 2" must be maintained during the fi rst 24” of venting

when penetrating combustible walls. The fi restop spacer (W500-0292) supplied with the unit should be used to

maintain this clearance. The fi rst two feet of outer 7” diameter vent pipe, from the appliance must be wrapped in the

1 inch thick insulation sleeve (supplied) as well as having a 1 inch air gap. Thereafter a 1” clearance to combustibles

may be maintained using fi restop spacer (W615-0044 for use with fl exible venting or rigid venting.)

This application occurs when venting through an exterior

wall within 24” of the fi replace collars. Having determined the

air terminal location, cut and frame a hole in an exterior wall

with a minimum rectangle opening of 11 1/2” x 11 1/2”.

IMPORTANT: For optimum performance, The stove pipe

should rise ¼” per foot of run.

1. Assemble the shield to the spacer as shown, using the

3 shorter screws supplied.

The shield is meant to protect combustible materials within

the wall. If the shield is deeper than the combustible portion

of the wall, cut to fi t.

2. Apply a bead of caulking all around and place the fi restop

spacer over the framework to restrict cold air from being drawn

into the room or around the stove. Ensure that both spacer

and shield maintain the required clearance to combustibles.

Secure the spacer in place using the 4 longer screws sup-

plied. Once the vent pipe is installed in its fi nal position, apply

sealant between the pipe and the fi restop spacer.

HORIZONTAL INSTALLATION

FIGURE 16